By Jose Ximello-Quiebras, Department of Physics, University of Konstanz; Johannes Junge, New Materials Group, Department of Physics, University of Konstanz; Sven Seren, Head of the New Materials Group, Department of Physics, University of Konstanz; Giso Hahn, Department of Physics, University of Konstanz; Ernst Epple, CTO, Lotus Systems GmbH

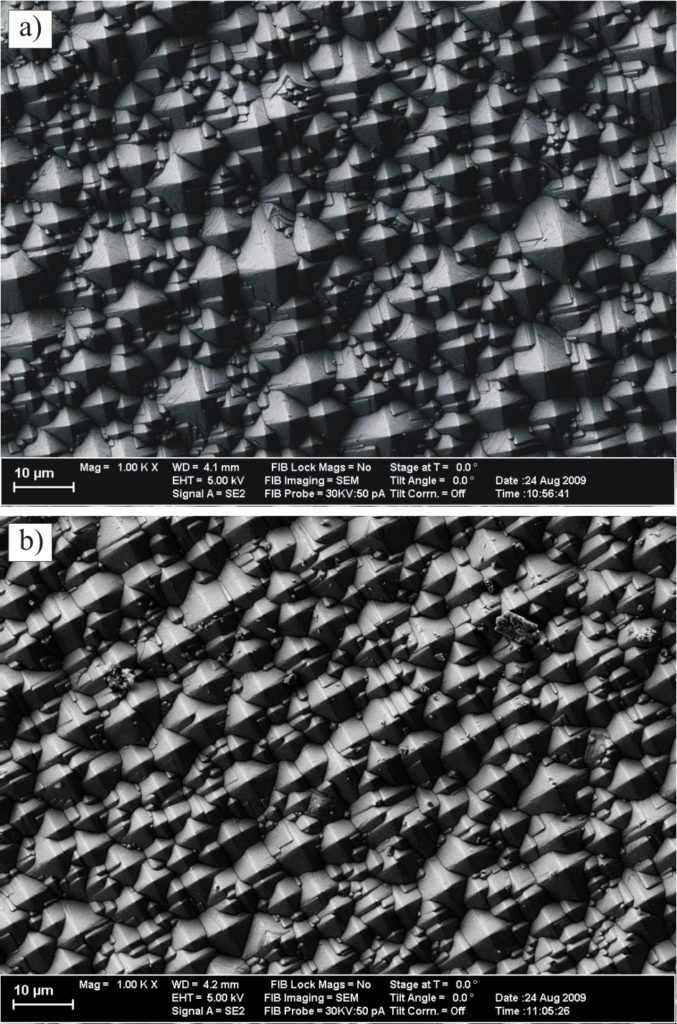

Texturization of (100) monocrystalline silicon (mono-Si) for solar cells is still an issue in the industrial production of standard screen-printed mono-Si solar cells. This fact is due to the properties of isopropyl alcohol (IPA), which is used together with potassium hydroxide (KOH) in the standard etching solution KOH-IPA (or used with sodium hydroxide NaOH in NaOH-IPA). The low boiling point of IPA (82.4°C) limits the etching temperature and thus the processing speed. Furthermore, KOH-IPA etching solution is very sensitive to the wafer pre-treatment characteristics of as-cut mono-Si wafers. Two ways to overcome these disadvantages are presented in this paper. The first approach involves the use of a high boiling alcohol (HBA) instead of IPA in the standard KOH-IPA etching solution. This allows higher etching temperatures to be used, without evaporation losses of the alcohol, but with reduced etching times. The second approach consists of using a closed etching bath in which vacuum (low-pressure) steps (i.e. pressure oscillations between atmospheric and below-atmospheric pressure) are achievable; in addition, a cooling system located on top of the etching bath allows the liquefaction of the evaporated IPA. The second texturing approach considerably decreases the etching time of mono-Si wafers. Examples of mono-Si wafers were textured using the new KOH-HBA etching solution and then processed into solar cells; the current-voltage results of the processed solar cells are presented.