Bifacial with transparent backsheet (bifacial TB) or bifacial with dual glass (bifacial DG), which one is more competitive? Based on a study of the two types of bifacial products and a long-term outdoor performance test carried out by JinkoSolar, comparisons from multiple perspectives are discussed below.

1. Weight

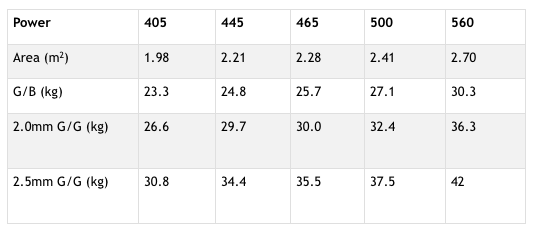

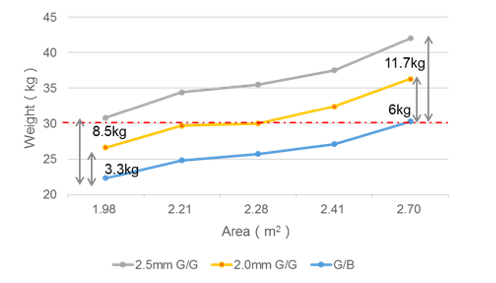

Since 2019, solar modules have become more and more diversified, but the trend toward larger size and higher power is a given. Along with the size increase, the module weight is also increasing. Compared with dual glass, the transparent backsheet can successfully decrease module weight and the difference between the glass-transparent backsheet module and the dual glass alternative increases with the growing module size. For the 410Wp product, the weight difference is only 3.3kg, but for the future 560Wp products (estimation based on the trend toward increased power and efficiency), the difference rises to up to 6kg. Using a transparent backsheet as the encapsulation material for the rear side can keep module weight under 30kg when the module size is as large as 2.7m2, which benefits installation and transportation, as well as cutting down BOS cost.

2. Mechanical properties

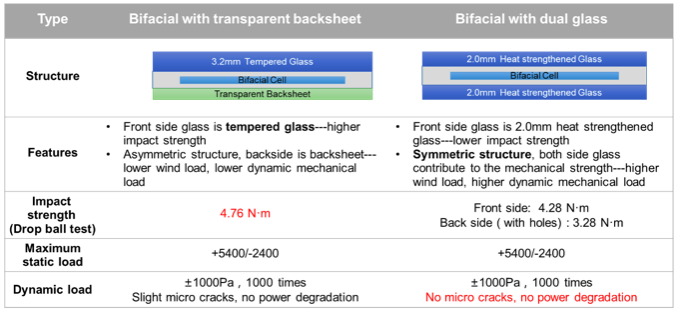

The front side glass of the bifacial TB is a tempered 3.2mm, whereas the front side glass of the bifacial DG is a heat strengthened 2.0mm. Owing to tempered glass having higher impact strength, the bifacial TB has lower risk if used in regions prone to weather conditions such as hail. The bifacial DG has a symmetrical structure, with the glass on each side contributing to its mechanical strength, providing it with a higher wind and dynamic mechanical load. In some regions with high wind speed (wind load higher than 2400Pa), the bifacial DG means lower risk, whereas the bifacial TB can also be used with extra fixing equipment. In fact, the certified 5400pa snow load/2400pa wind load can meet the design requirements of most power plants. From this point of view, the bifacial TB and bifacial DG are basically the same in terms of mechanical properties.

3. Reliability in extreme weather

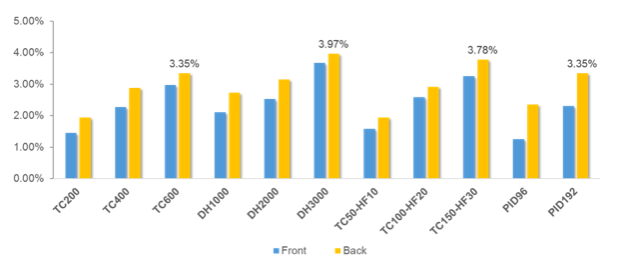

Dual glass modules are known for their excellent vapor resistance. The risk of breakage for dual glass modules is lower when compared with normal products in an environment with high humidity, such as offshore areas and floating projects. The 30-year lifetime of a bifacial TB is based on using a transparent backsheet with fluoric materials on both sides, combined with vapor-resistant POE. The outer layer of the transparent backsheet is Dupont Tedlar film, which is anti-aging and anti-corrosion. The inner layer is fluoric coating(thicker than 10μm)which can effectively block UV and maintain the backsheet’s excellent mechanical properties in extreme environments. POE is a polymer material with a more stable molecular chain without acid groups and has better water resistance than EVA. The combination of the PVF-based transparent backsheet and POE contributes to its good performance in the strict reliability test up to DH3000, with degradations all within 4%.

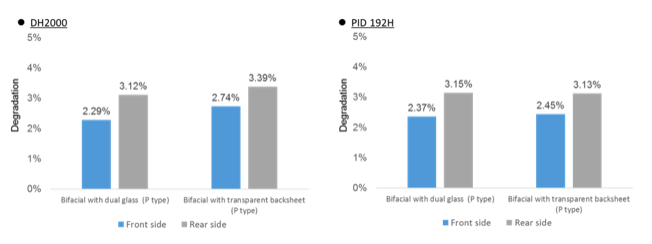

In the DH2000 test, the degradation of the bifacial TB is slightly higher than that of the bifacial DG (POE is also used as the encapsulation material). In the PID192h test, the degradation of the bifacial TB and bifacial DG is basically the same, with both within 4%. For most regions, these two types of bifacial module can withstand the 30-year humidity and heat impact, maintaining a low degradation level. Only in extreme hot and humid environments is the bifacial DG more competitive.

4. Anti-UV properties

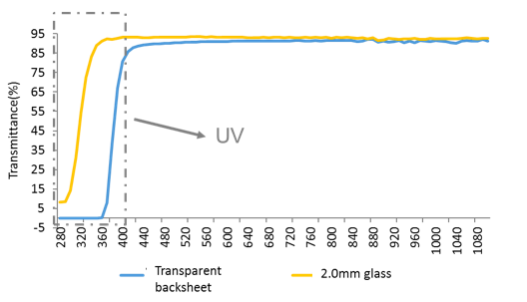

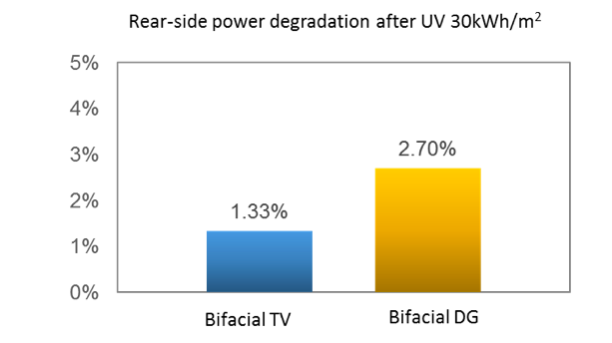

There is an obvious difference in ultraviolet transmittance of a transparent backsheet and glass. UV transmittance of a transparent backsheet is less than 1%, whereas that of glass is 40-50%. Due to the common use of high-transparency POE for bifacial modules, the bifacial DG cannot block the damage of transmitted UV from the rearside to the packaging materials and cells, while the transparent backsheet can block UV and thus protect cells and packaging materials.

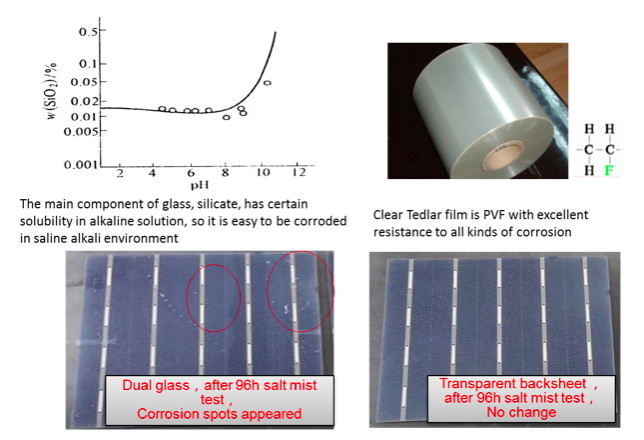

5. Resistance to saline alkali corrosion

The main component of glass is silicate, which has certain solubility in an alkaline solution. It is easily corroded in an alkaline environment and forms white spots which are difficult to clean. The transparent backsheet has excellent resistance to saline alkali corrosion, thus the risk of the TB module is lower in greenhouse, saline-alkali soil and PV agricultural projects.

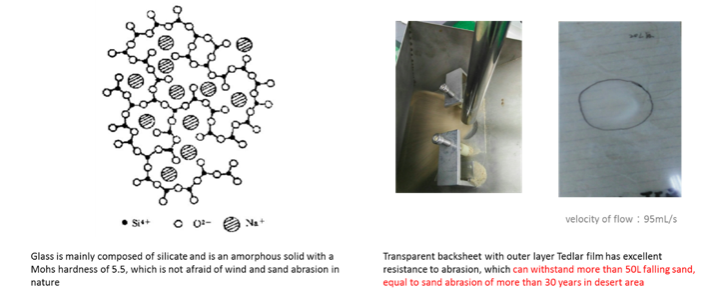

6. Resistance to abrasion

Glass is a hard inorganic material, with almost no abrasion in a sandy region. The outer layer of the transparent backsheet is Tedlar film, which can withstand more than 50L of falling sand. The transparent backsheet can also withstand more than 30 years of sand abrasion in a desert area.

7. Stain-resistance and ease of cleaning

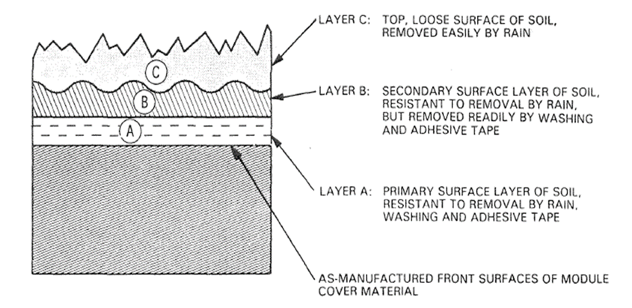

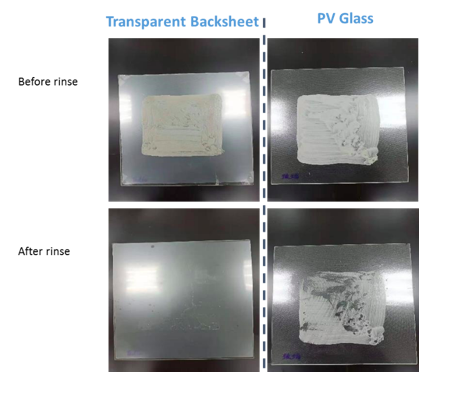

The stain-resistance of the transparent backsheet makes the rear side of a bifacial module easier to clean and maintain than glass. There are three soiling layers on the surface of modules operating outdoors, as shown in Figure 8.

There are many fluorine atoms on the surface of a transparent backsheet, which is therefore extremely electronegative. As a result, the soiling on the surface of the transparent backsheet is dust, which is combined with the backsheet through physical absorption. These type of stains are very easily cleaned by rain; thus, they tend not to accumulate on the surface of the backsheet and will not have an effect on energy generation. Glass is hydrophilic, meaning that, during long-term operation, mud spots can form via a mixture of ash and rainwater and dry on the surface of the glass. In contrast, there is no obvious dirt on the surface of the transparent backsheet, as shown in Figure 9.

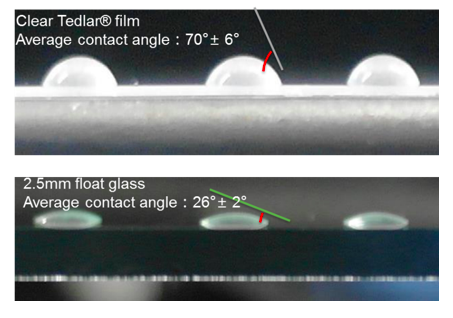

The surface of the transparent backsheet is hydrophobic, meaning that water droplets easily roll off and remove dust. By way of contrast, a glass surface is hydrophilic, the water droplets will spread and stains will form a stronger connection with the surface, making the glass more difficult to clean. For a comparison between the ease of cleaning of a transparent backsheet and glass surface refer to GB / T 9780-2005, as shown in Figure 11. Only by water washing (flow rate 0.3-0.5m/s) for 10s, can the dirt on the surface of a transparent backsheet be cleaned, while there are still many residual stains left on the glass surface.

8. Energy generation

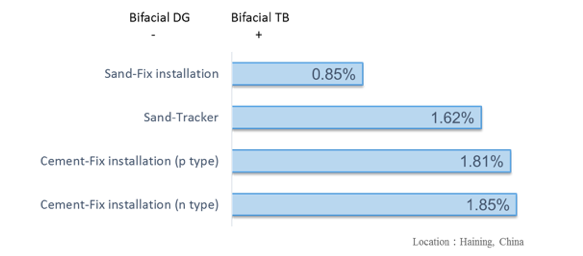

Energy generation is undoubtedly the most important property. In 4 different field tests, the bifacial TB has more energy generation compared with the bifacial DG. The detailed energy gain is shown in Figure 12.

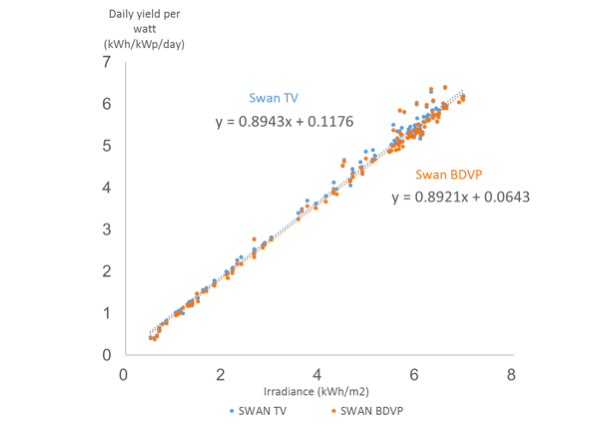

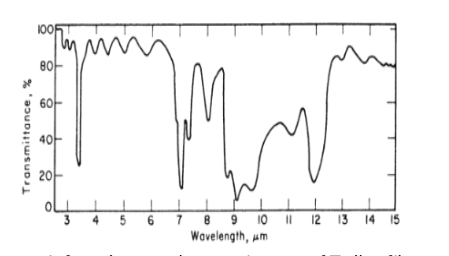

Analyzing the irradiance data and daily yield per watt of a cement-fixed installation (P type) project, the daily yield of the transparent backsheet module is higher when irradiance is higher. It is also obvious that the slope of the fitting function of the TB module is greater, so the power generation difference between the bifacial TB and bifacial DG will increase under high irradiance. The higher power generation of the transparent backsheet originates from the lower operating temperature. Glass becomes opaque at wavelengths longer than approximately 3 μm, while the transparent backsheet in the infrared spectrum is transparent to the heat dissipation of solar cells from the back of the module. The heat dissipation mechanism of the bifacial TB is more comprehensive, so it can have a lower operating temperature.

Summary

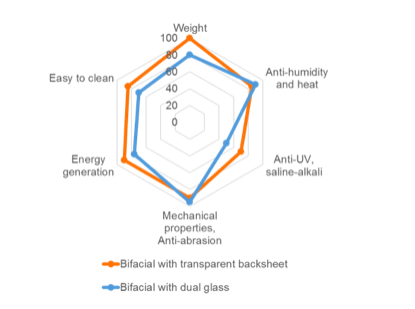

Bifacial with transparent backsheet and bifacial with dual glass have their own advantages and disadvantages. The radar chart can help customers evaluate the two products and their application scenarios more comprehensively. As can be seen from the figure below, the bifacial TB is an all-round module with balanced performance in different aspects. The bifacial DG is better in terms of its resistance to humidity and mechanical properties, but inferior in terms of resistance to UV, saline-alkali, weight and ease of cleaning. The energy generation is also slightly lower than that of the bifacial TB.

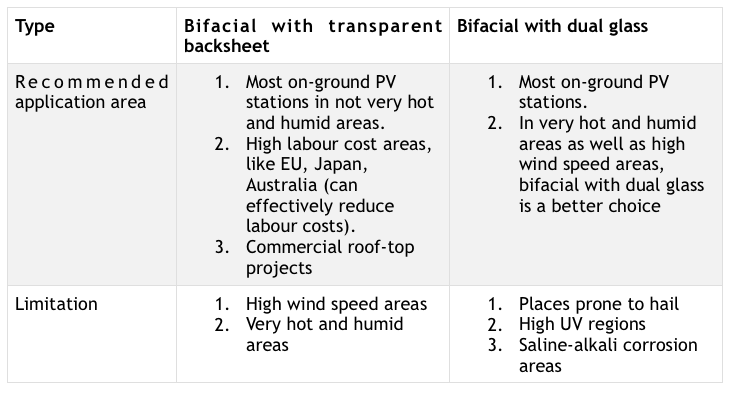

Based on the above analysis, application scenarios of these two kinds of bifacial modules are as follows: