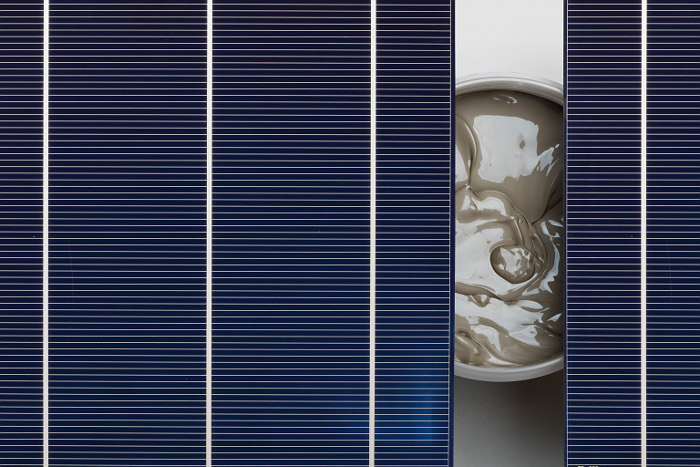

Major metallization paste producer Heraeus Photovoltaics new APAC Technology Development Center (APAC TDC) in Shanghai, China is aiming to further reduce lead times for product modifications and deliveries to around only one week.

Having opened its first dedicated R&D facility in China a year ago, the APAC TDC is a further expansion of the Product Modification Lab (PML) at the facility, the second largest R&D centre operated by Heraeus Photovoltaics.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

Or continue reading this article for free

Dr. Weiming Zhang, Senior Vice President Innovation, Heraeus Photovoltaics said, “We have established this center in China to increase broader collaboration with all potential partners along the PV value chain. The PV business is no longer a marathon, it’s a sprint that demands lightning-fast response.”

Quicker response times have become a key requirement due to the myriad of PERC (Passivated Emitter Rear Cell) variations being developed and ramped into volume production as well as other R&D activities on heterojunction cells.

Heraeus announced the opening of the new facility during SNEC 2016 being held in Shanghai, China this week. The company also launched new pastes for PERC cells at the show.