Agfa Specialty Products has introduced ‘UNIQOAT,’ its next generation of polyester-based backsheet product. UNIQOAT eliminates the risk of backsheet delamination as it is manufactured as a single layer backsheet and achieves a level of reflectivity. The new product was showcased at SNEC 2017.

Problem

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

Or continue reading this article for free

In the design of a PV solar module, one of the performance targets is the maximization of the light capture by the cells. In a completed module about one quarter of the radiation is not reaching the cells and cannot contribute to the generation of electrical power. The sun rays that enter a module via the gap between the cells are lost for power generation unless the backsheet can reflect them to reach the cells. Today, the most used polyester-based backsheet structures feature two or three film layers that are laminated together using an adhesive component. Such laminate structure is the weakest link in a solar module because the adhesion strength between its layers is far lower than the bonding strength between the other components in the module.

Solution

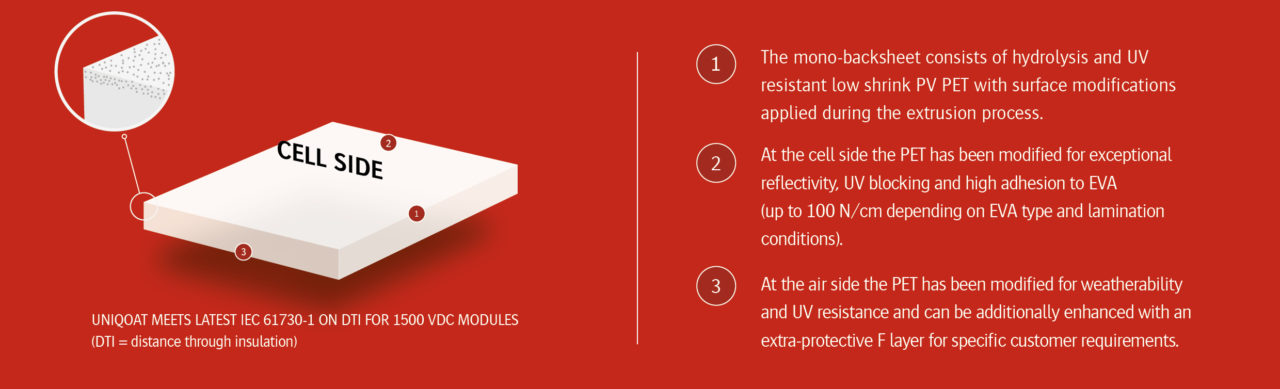

Agfa’s UNIQOAT backsheet achieves a level of reflectivity that is probably the highest in the market today and thereby offers increased power output of solar modules, according to the company. By design UNIQOAT eliminates the risk of backsheet delamination because it is conceived and manufactured as a single layer backsheet. During the extrusion process the hydrolysis and UV resistant polyester is surface-modified to face the challenges to which it will be exposed and to actively contribute to more reliable and durable solar modules and offers the potential for significant cost reduction.

Applications

PV module lamination.

Platform

UNIQOAT as a mono-backsheet that eliminates the cost of a lamination adhesive and of managing a complex mix of lamination films from a variety of suppliers. UNIQOAT backsheets are offered to the market in three product types depending on thickness and weathering properties: UNIQOAT 315, UNIQOAT XR 315 for extra reflectivity and UNIQOAT XR 330F for additional protection. Meets IEC requirements and the new IEC DTI.

Availability

April 2017 onwards.