Trina Solar has unveiled the results of outdoor tests in two project locations, which suggest that its Vertex module presents advantages in field energy yield performance when compared with 182 modules. Testing took place at the National Photovoltaic Quality Inspection Center (CPVT) in Yinchuan, north western China and the National Photovoltaic Science and Technology Laboratory (PVST) in Changzhou.

Yinchuan field testing

The CPVT outdoor test site was in Yinchuan, an A level light irradiation area with a solar spectrum close to the standard AM 1.5. Annual radiation intensity is 500W/m2 and above for more than 2,000 hours, with average daily direct irradiation of 5.75 kWh/m2. Yinchuan has a temperate continental climate, with dry and hot summers and wide variances between morning and evening temperatures. The project began in April 2021 and is expected to be completed by April 2022.

Module installation overview

Location: Yinchuan (38.47°N)

Tilt angle: 40°

Installation height: 1m

Surface: sand

Data collection method: High precision DC meter + SG20RT-20 inverter

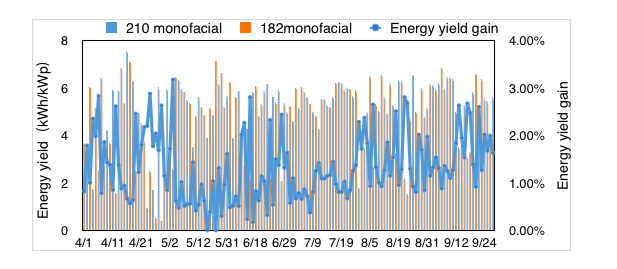

Data from April to September 2021 showed that the energy yield gain of the 210 mono-facial module was1.2% higher than that of the 182 mono-facial module.

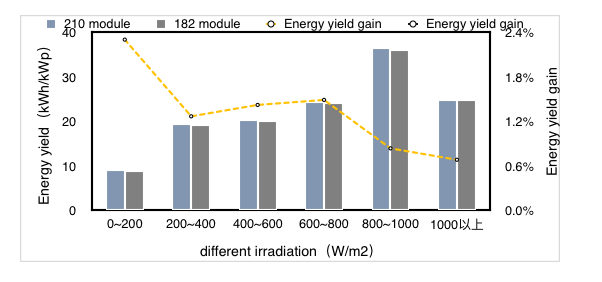

It is clear from the figure above that in days with low energy yield, the 210 module shows an obvious growth in energy gain. The comparison of different irradiation periods shows that 210 modules still have advantages in low irradiation performance in the A Level light irradiation area.

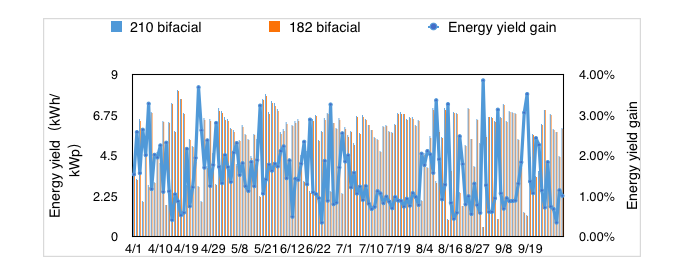

Data from April to September 2021 shows the benefit of higher bifaciality, with the energy yield gain of the 210 bifacial module 1.3% higher than that of the 182 equivalent.

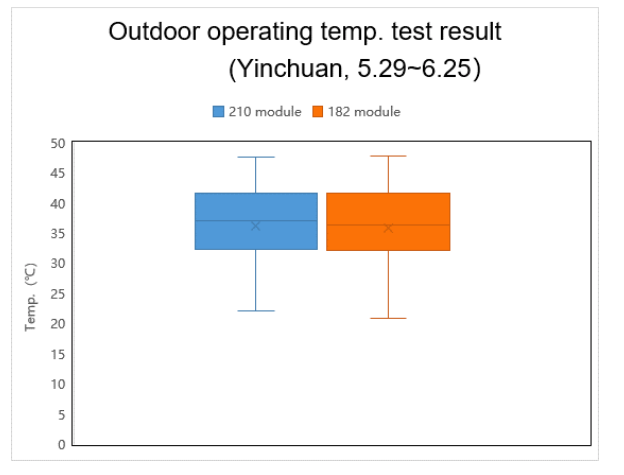

To calculate the operating temperature of the modules, four points were selected from each, and the test equipment strictly followed the accuracy specifications of IEC61724-1 Class A. The test results show that the operating temperature of the 210 module is basically the same as that of the reference module.

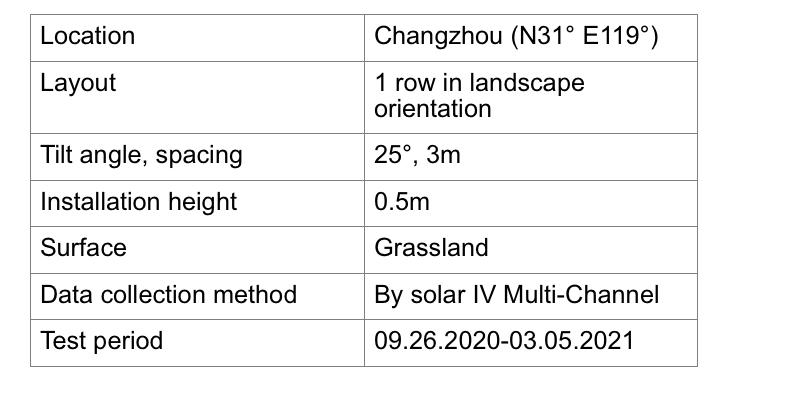

Changzhou field test research

The Changzhou PVST test field is located in Changzhou (119.97°E/31.83°N), with a northern subtropical maritime climate. Summers are hot and rainy with highest air temperatures usually above 36°C. Winters are humid and cold.

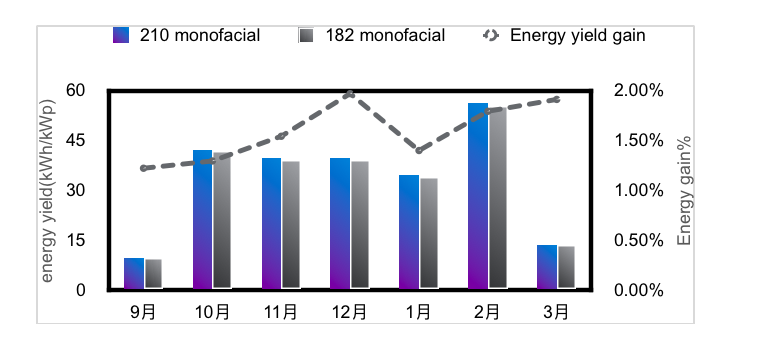

Testing began in September 2020. Data to March 2021 shows the energy yield gain of the 210 mono-facial module to be 1.6% higher than that of the 182 equivalent.

Analysis of reasons for the energy yield advantage of the 210 module

- Excellent low-irradiation performance

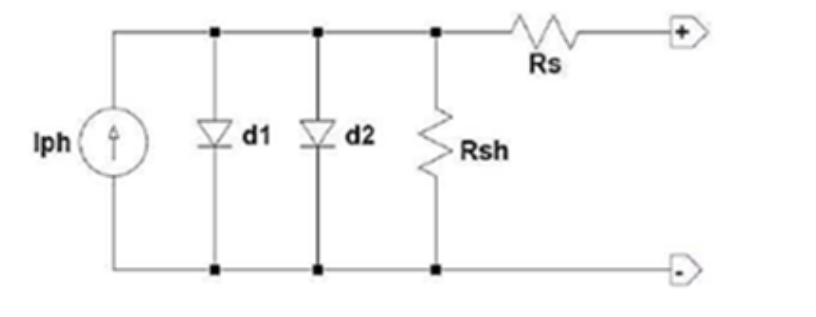

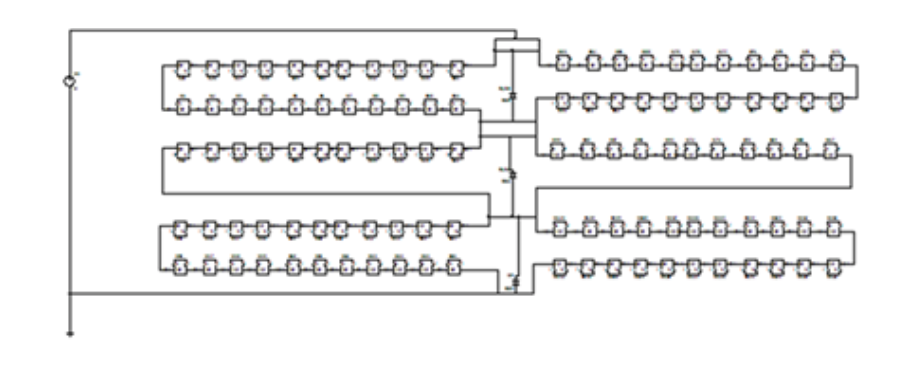

To study the benefits of 210 modules in terms of low-irradiation performance, model-based analysis was conducted on test samples with a double-diode model. The diode model is widely used to identify cell and module characteristics, such as the PAN file in PVsyst V6.85. On the basis of a traditional single-diode model, the double-diode also takes into account the composite loss in the depletion region so as to effectively verify the performance of the module under low irradiation.

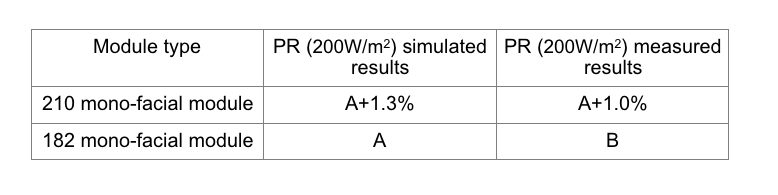

Using the diode model, the simulated and measured results of low irradiation module performance can be compared as follows:

The simulated results show that low-irradiation performance PR200W/m2 of the 210 module is 1.3% higher than that of the 182 module.

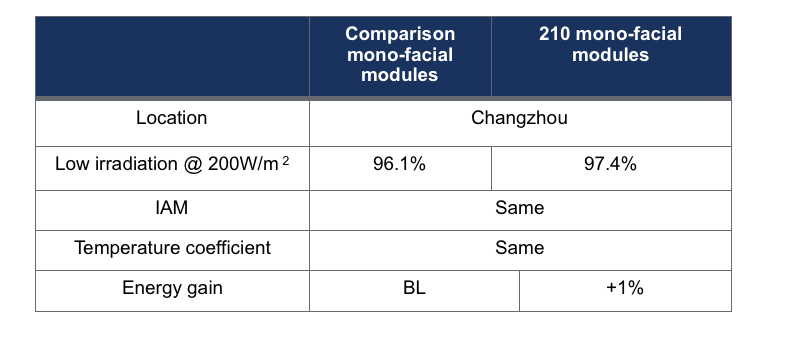

Meteonorm 7.2 is used to obtain meteorological data, with energy yield simulation performed in PVsyst V6.85.

With Changzhou as an example, it was found that low irradiation rises by 1.3% and energy yield by 1%

Note: The simulated results are based on PVsyst V6.85. Meteonorm 7.2 is used to obtain meteorological data. The differences between simulations and measurements include differences in meteorological data, uncertainty of power and uncertainty of test equipment.

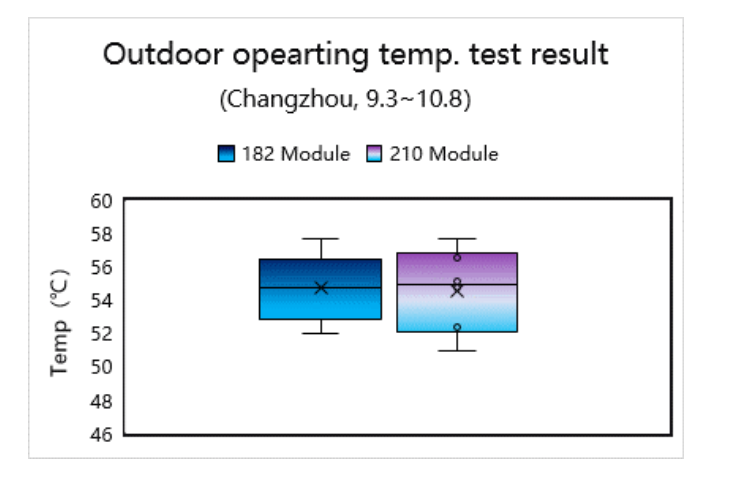

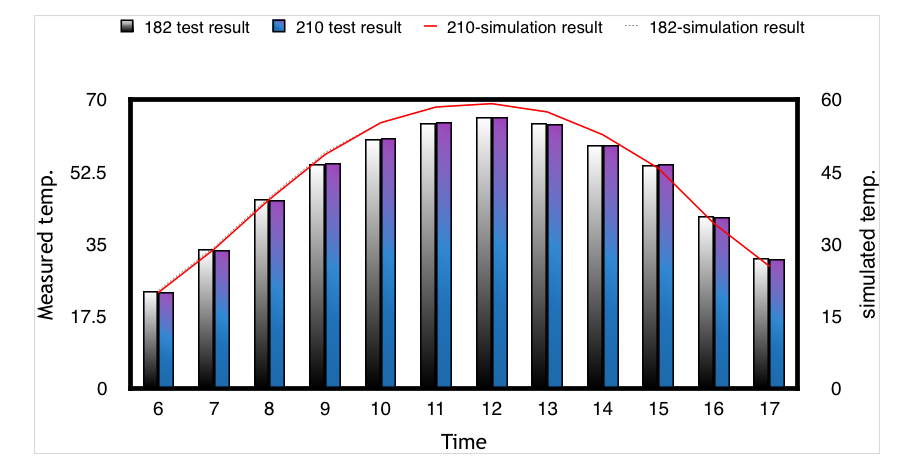

2. Operating temperature of the 210 module is lower than that of the comparison module, with energy yield higher during low irradiation periods.

The operating temperature of the modules was noted using an HIOKI thermocouple data collector. The results show no difference in temperature between the 210 and the comparison module. In fact, according to the irradiation weighted average temperature, the temperature of the 210 module is 0.5°C below that of the comparison module.

The PVsyst simulated results show that when the temperature coefficients of the modules are the same, the energy yield will increase by about 0.2% for every 1°C decrease in the operating temperature in Changzhou.

Summary

- Based on results from outdoor field testing conducted in Changzhou and Yinchuan under the same environmental and parameter settings, the low irradiation advantage of the 210 module, both monofacial and bifacial, produces an energy gain compared with the 182 module – the monofacial module up to 1.6% and the bifacial up to 1.3%.

- The 210 module demonstrated advantages in low-irradiation performance, resulting in an increase in energy yield.

- The loss of resistance would have minimal impact on heat performance, dispelling customer doubts about high current and low internal resistance value, the overall impact on energy yield being negligible.