ATW has taken part in an international PV technology exchange event in the Indian capital, New Delhi, with technology experts, manufacturers, R&D professionals and policy and market stakeholders from around the world gathered to explore pathways toward high-performance PV manufacturing and industry upgrades.

Discussions centred on manufacturing process innovation, technology collaboration and the enhancement of overall industry competitiveness.

Representing ATW at the event, Overseas Sales Director Senthil Raj delivered a presentation on the company’s full-process PV manufacturing equipment solutions, covering ingot, wafer, cell and module production.

Noting that, with global PV manufacturing continuing to evolve toward higher efficiency, stronger consistency and large-scale production, manufacturing equipment plays an increasingly critical role in yield control, process stability and system-level integration, Raj emphasized that the demand for mature, reliable equipment with long-term upgrade capability is steadily growing.

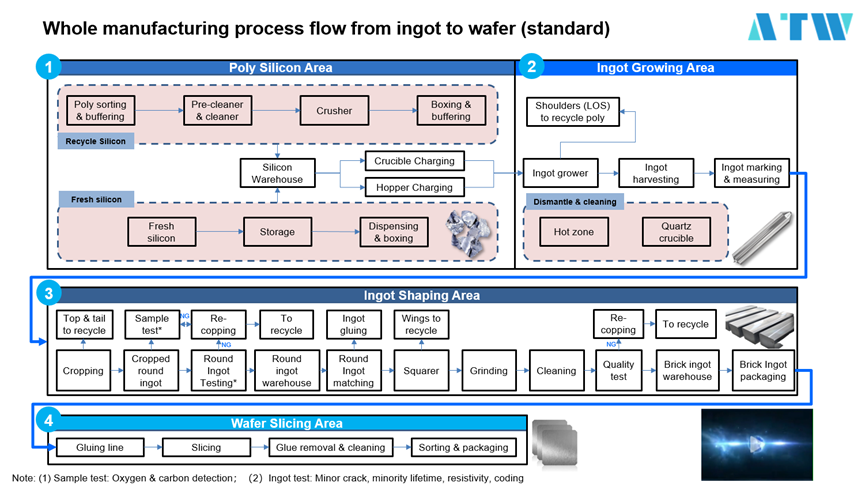

In the ingot-to-wafer segment, ATW provides integrated production line solutions covering core equipment, full-line automation and digital management.

Its solutions include monocrystalline ingot pullers, cropping, squaring and chamfering machines, as well as wire saws and sorting systems, enabling complete main-equipment package delivery from ingot pulling to wafer processing. Supporting systems including automated conveyor lines, storage and retrieval systems (AS/RS), AGVs and auxiliary feeding systems are deployed to connect individual processes and enable continuous automated production from ingot to wafer.

On this basis, ATW deploys a plant-wide MES system to unify the management of equipment and manufacturing data, supporting production scheduling, output control, quality management and process recipe management. This integrated solution effectively reduces labour dependency and operating costs, while improving line efficiency. By linking full-process manufacturing data, it enables quality correlation across upstream and downstream processes, driving improvements in overall plant yield and product quality. Real-time visualization of equipment status and production output provides data-driven support for management decision-making, helping customers accelerate their transition toward smart manufacturing.

Multiple core ATW products and integrated solutions have already been widely adopted by leading industry players worldwide, enabling capacity expansion and a reduction in operating costs.