The rapid growth of the PV industry in China has been the driver behind the development of high-efficiency solar cells including N-type bifacial, HJT and half-cut, with cost reduction and efficiency improvements having become the primary objectives for the entire industry. In truth, however, an increase of a mere 0.01% in solar cell efficiency involves significant effort. According to forecasts from the CPIA, the market share for TOPCon and HJT cells will rise to 35% by 2025 with, theoretically, N-type cells featuring low oxygen content and high conversion efficiency likely to achieve higher efficiency than their P-type equivalents.

The latest phase of cell efficiency improvements requires superior N-type mono-Si cells which feature lower oxygen content, less resistivity and a longer minority carrier lifetime, with a better engineered and proven crystal growth furnace a prerequisite to producing such cells.

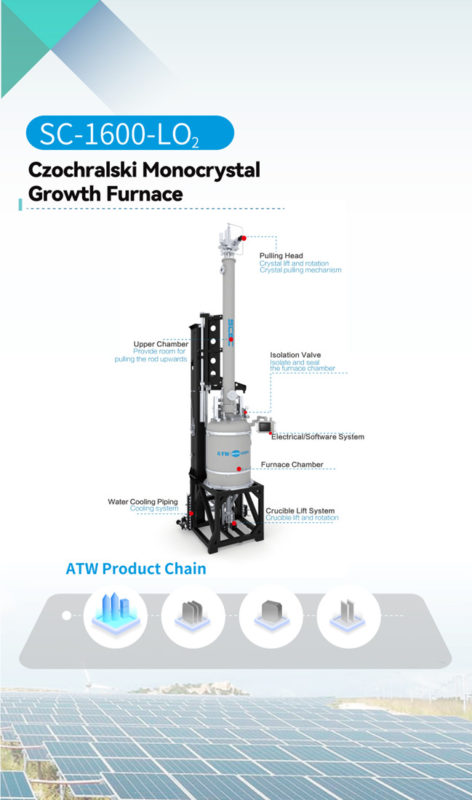

The bigger the furnace body and crystal size, the longer it will take to stabilize the silicon melt temperature, and this will in turn have an adverse effect on the stability of oxygen content in a single crystal. To address this technical issue, Autowell subsidiary Songci Electromechanical has undertaken significant development, verification and testing to finally come up with a solution for lowering the oxygen content of mono-Si cells – the SC-1600-LO₂ crystal growth furnace.

The Songci R&D team carried out extensive research into the mechanics of concentric circle defects occurring in N-type single crystals as well as the corresponding oxygen control technology. The numerical simulation of the Czochralski process and the basic study of concentric circle defects enabled the team to discover a correlation between the probability of concentric circle defect and the oxygen content of a single crystal. Leveraging low oxygen content crystal growth technology and the optimization of a furnace’s software and hardware, it was able to reduce the proportion of concentric circle defects by 50%.

Compared to the oxygen content level of a typical silicon cell, the new crystal growth furnace can reduce this by more than 24% under the same conditions and cell efficiency is enhanced by 0.1% according to test line data.

Design steps in the Songci Electromechanical oxygen content reduction scheme:

- Simulate hot zone process and take fluid flow path into account, to make sure the opening location and fluid pipe routing are designed to perfectly fit the pipes in the furnace. In this way, impurities like oxygen can be removed as far as is possible.

- Add functional module for oxygen control to software control algorithms and turn on oxygen removal function from time to time without affecting crystal growth; other impurity removal modules will be incorporated later in the same manner.

- Adjust part of the process package to enhance matching between process and hardware.

The Songci Electromechanical crystal growth furnace can not only deliver efficiency improvements but also enable customers to quickly recoup equipment costs. Several high profile PV companies are currently testing low oxygen content crystal growth using Songci laboratory furnaces.

With over a decade of manufacturing expertise, the company has an impressive history of achievement up to 2022: over 2,000 units of equipment sold annually at a six-fold increase in order value. Among clients are industry leaders including Trina Solar, Qinghai Jinko Solar, JA Solar, Yuze Semiconductor, Hoshine, Zhongchengyu Energy and, notably, India’s Adani Solar, marking the delivery of the country’s first monocrystalline silicon rod.