JinkoSolar has won a large project in India with two of the largest local EPC companies to deploy almost 500MW of its Tiger Pro high-efficiency modules.

In a global PV market, India included, dominated by large ground-mounted power plants, more and more customers are showing an increased interest in tracker costs. In the tracking system scenario, the Tiger Pro 182mm module series can ensure more advantageous costs when compared to other larger modules.

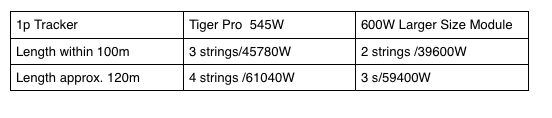

Whether BOS costs can be reduced or not depends on the possibility of reducing system-side costs. First of all, looking at the largest part of EPC composition, besides the components, the largest is the tracking system. Accounting for up to 19% of the total BOS cost, the tracking system is an element that cannot be ignored. Due to tracker tolerance to the driving devices and tracker structure, the length of the tracker is limited in current and future designs. The dimensions and electrical performance of modules determines the number of strings installed on a single tracker. Therefore, in theory, the so-called low voltage which can increase the number of modules on a single string is difficult to achieve in practical applications.

The dimension and electrical performance of 182mm modules has maximized the total power on the tracker, which can then make perfect use of its maximum design length for the lowest cost per watt. Considering that time and labour costs involved in tracker installation are much higher than those for modules, reducing the number of trackers required can greatly lower overall installation costs.

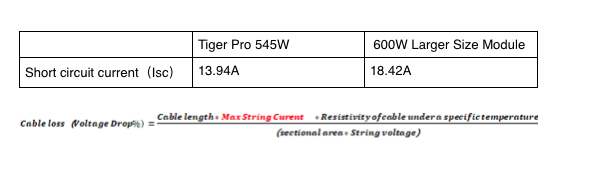

Secondly, the power generation of modules is the biggest factor affecting LCOE. High current is in itself not a big challenge for system safety, the issues for the industry being more how to achieve the optimal balance between cable selection costs and mitigating the loss of power generation caused by high current.

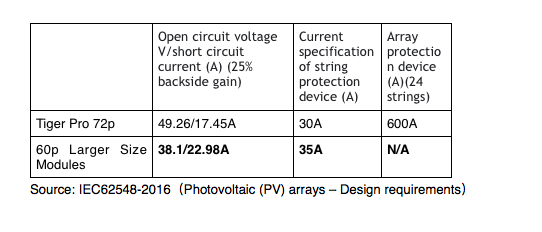

It can be seen that, if the same cable is selected, the higher the component current, the greater the cable loss. If a thicker cable is used to reduce cable loss, its cost will increase. In addition, in terms of current safety, the 182mm module does not need to upgrade current protection and there is no need to incur the cost of additional devices.

From the above, it is clear that higher current requires protection devices of higher specifications to ensure module safety. 182mm modules can not only ensure higher safety levels, but can also reduce the cost of additional protection devices.

Compared with other products in the industry, the 182mm module has, in many aspects, proven to be the best choice for achieving optimal tracking system costs and it has therefore become the most economical and safest mainstream photovoltaic module available on the market. Tiger Pro high-efficiency modules are steadily advancing in global market deployment thanks to positive recognition from customers.