By Ringo Koepge, Research Scientist , Fraunhofer CSP; Frank Weget, Senior Staff Expert, Hanwha Q CELLS GmbH; Sven Thormann, Hanwha Q CELLS GmbH; Stephan Schoenfelder, Fraunhofer CSP

Minimizing the breakage rate of silicon wafers and cells during production has been one of the key issues for reliable and productive solar cell manufacturing. However, the root causes of damage or breakage,

as well as the mechanical characteristics of manufacturing processes, are not completely understood. In the study described in this paper the change in mechanical strength and the damaging of wafers and cells was analyzed in an industrial cell manufacturing line in order to detect critical process steps and handling operations in certain processes such as etching, diffusion, screen printing and firing. An analysis and discussion of damage sources is presented which offers more insight than the conventional study

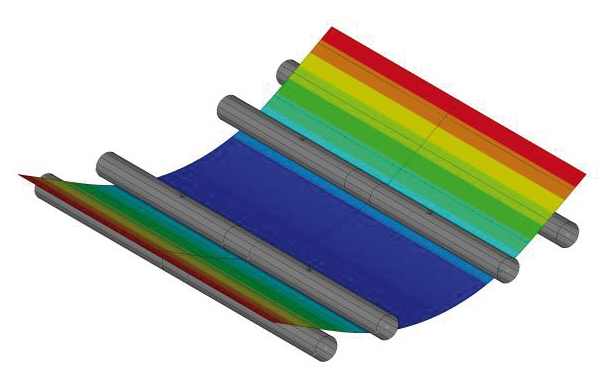

of breakage rate that is mostly performed by cell manufacturers. In a systematic experimental study, 19 different locations in the production line were investigated. The mechanical strength of 800 wafers or cells at different points in the cell line was subsequently determined using the four-line bending test and the statistical parameters for the Weibull distribution. It was discovered that dramatic changes in strength

occur at different process steps because of the change in defect structure; there were also found to be several positions at which no further damage was detected. This method of investigation can therefore be used as

a fingerprint of a cell line in respect of yield and breakage rates. Individual processes can be identified that indicate high damage potential, although the actual breakage could occur in a subsequent process step.