By Strategy and Planning Department, LONGi Silicon Materials Corp.

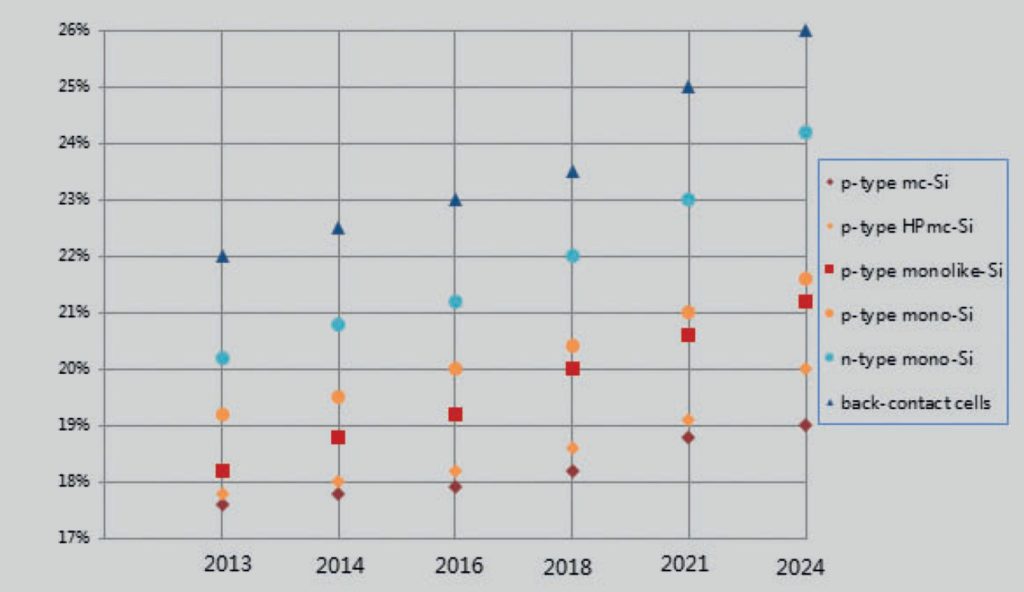

One question to emerge in recent years is whether monocrystalline silicon (mono-Si) or multicrystalline silicon (mc-Si) will become the dominant mainstream technology in the future PV industry. However, despite all the arguments, the market share of mc-Si seems barely changed, while the market share of mono-Si has not increased significantly. The reasons why mono-Si has not made progress have been extensively mentioned in the literature and will therefore not be covered here; rather, the objective of this paper is to discuss several benefits of mono-Si.