By Ingrid Romijn, ECN Solar Energy; Lang Fang, Yingli Solar; Ard Vlooswijk, Tempress Systems BV

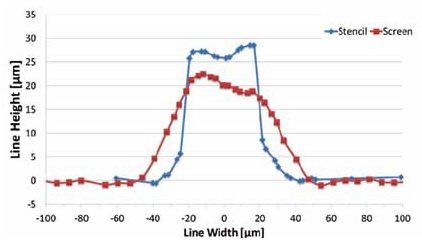

This paper presents examples of recent process developments at ECN in silicon solar cells on n-type monocrystalline base material. For all PV manufacturers, the challenge is to increase module efficiencies while maintaining low production cost. An effective way to move to higher and more stable efficiencies, using low-cost industrial-type processing, is n-type solar cell technology. The solar cell considered in this paper is the n-pasha cell – a bifacial solar cell with homogeneous diffusions and screen-printed metallization. The n-pasha cell is currently produced on an industrial scale by Yingli Solar; in 2011 a maximum solar cell conversion efficiency of 19.97% was obtained using this cell concept on 239cm2 n-type Cz at the ECN laboratory. The focus of the paper will be increasing efficiency by optimization of the cell process, in particular the front-side metallization, and by improvements to the rear-surface passivation. These two steps have contributed an increase in efficiency of 0.8%, allowing cell efficiencies of 20% to be reached.