By Sreenivas Murty Dasari, Deputy Manager of the Department of Cell Technology and Process Engineering, TATA BP Solar India Ltd; K. V. Nagaraj, Manager in Quality and Reliability, TATA BP Solar India Ltd; S. Saravanan, Deputy Manager of the Department of Cell Technology and Process Engineering, TATA BP Solar India Ltd; Prakash Suratkar, Head of the Technology and Process Engineering Department, TATA BP Solar India Ltd; T.S. Keshav Prasad, Executive Vice President, TATA BP Solar India Ltd

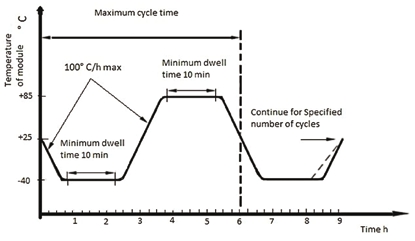

Crystalline silicon solar modules installed in the field are exposed to atmospheric conditions and experience stress, which induces a wear-out phenomenon in various parts of the modules and degrades performance over time. The performance eventually reaches a point where the output power falls below an acceptable level. Thermal cycling (TC) and damp heat (DH) are two important reliability tests for estimating infant failures related to materials and the manufacturing process, as well as providing the information on performance degradation with respect to time. In this study, modules composed of 156mm × 156mm multicrystalline silicon cells were subjected to TC and DH tests. By applying acceleration models, such as the Norris-Landzberg model for TC and the Hallberg-Peck model for DH, the minimum guaranteed life was calculated. The electrical and reliability results were interpreted and explained on the basis of the respective models.