JinkoSolar’s new Tiger Pro series redefines the highest power in the PV industry with 580W, which also emphasizes that JinkoSolar has entered a new era for with their its modules with of 500W. The response to the launch of the Tiger Pro series has been overwhelming. JinkoSolar is turning the attention of the industry to the technology rather than the size of the silicon wafers. Meanwhile, the industry has given positive feedback on the system compatibility and system cost reduction of the Tiger Pro series.

The design and application advantages of the new Tiger Pro products on the system side are as follows:

1. Lower Voc, lower temperature coefficients:

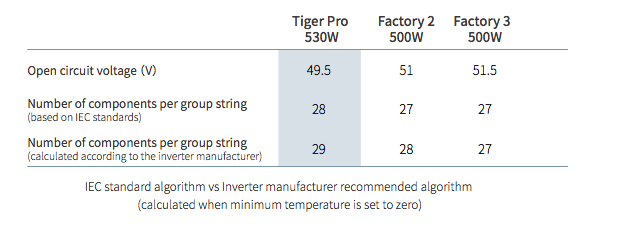

The low Voc and temperature coefficients of the modules can increase the number of modules on the unit group string, and if the DC side capacity of the project is known, the total number of strings in the project will be reduced. It is well known that if the total number of modules in the system is reduced, on the one hand, the corresponding cable and mounting system costs will be reduced and, on the other hand, the labor costs involved in the project will be significantly reduced as well. Especially for large photovoltaic projects, the capacity ratio of the whole project can also be improved. The Voc under standard conditions for the new Tiger Pro module is 49.5V (double-sided).530W@STC=25℃ G=1000W/m2, AM=1.5).

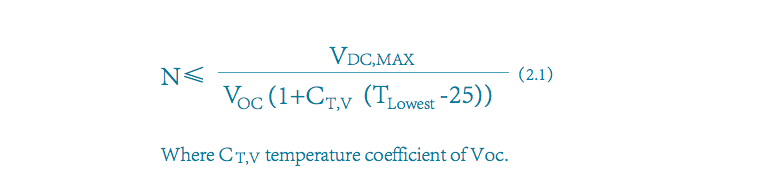

Assuming that the lowest temperature ever recorded in a location is 0 degrees, using 530W modules in a 1500V system on the DC side, the temperature coefficient is -0.28%/ C. According to the standard calculation method recommended by IEC62548, each series of components can take up to 28 strings per group. We also use modules from two other manufacturers for comparison.

Below is a screenshot of the IEC standard:

This is the standard algorithm recommended by IEC, where Voc is open-circuit voltage under standard conditions, Vdcmax is system voltage, and Tlowest is minimum temperature ever recorded.

If the calculation method recommended by some inverter vendors is used, the operating temperature of the modules will be higher than the ambient temperature, due to the consideration of the heat caused by solar irradiance, then the temperature correction value of the module’s Voc will be increased, and a single set of strings can connect more modules.

2. Higher efficiency and power levels:

More efficient, the area of the entire PV plant will be reduced, which can bring a significant reduction in land lease area of the project; higher power levels, for the cost of the stand, will also lower the cost of an allocated single-watt stand, especially at low wind speeds. Of course, efficient module products with high-power will also bring greater power generation benefits to a project.

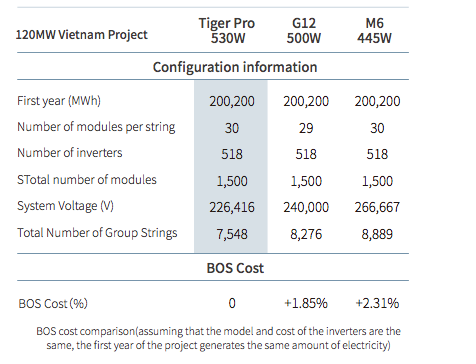

Taking a location in Vietnam as a research object, we used Tiger Pro 530W modules and found other types of module to compare BOS cost differences. We can see that the BOS cost of modules varies due to different power levels, and Tiger Pro 530W modules perform better in comparison.

3. Higher compatibility with tracking mounting system and lower LCOE

Through communication with numerous manufacturers, the size and weight of Tiger Pro products is more friendly for the design of a tracking mounting system. Generally speaking, the tracking mounting system is composed of columns, spin axes and purlin bars, and the cost of the mounting system is also composed of these elements; and among the mounting system costs, spin axes account for the largest proportion, generally 25-35%. Based on the relationship between the torque load and the length of the modules, it can be considered that the torque load is proportional to the square of the length of the component.

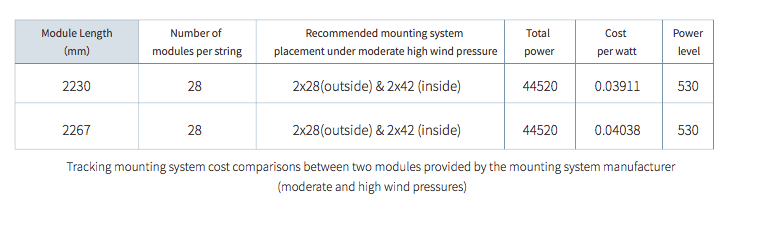

For the Tiger Pro 72 tiling ribbon/transparent backsheet module, the module length and weight will be smaller than those of other manufacturers, due to the use of tiling ribbon and transparent backsheet technology resulting in reduced shaft costs. As the most significant part of total expenditure, this obviously has a greater effect on overall cost.

In addition, load area decreases as the length of the module is reduced, as well as the corresponding wind and snow load, which indirectly lowers the cost of the fixtures for the mounting system.

According to the model provided by the mounting system manufacturer, the cost of single-watt for the mounting system is mainly inversely proportional to the size of power in low-wind pressure areas, so the higher the module power, the lower the cost of single-watt for the mounting system; however, in high-wind pressure areas, the cost of single-watt for the mounting system is positively related to module length. Comparing Tiger Pro with modules from other manufacturers at the same power according to the data provided by the tracking mounting system manufacturer, we can see that although the panels have the same power, the cost per watt of the mounting system is different due to the different length of the modules.

4. High compatibility between bifacial modules and inverters

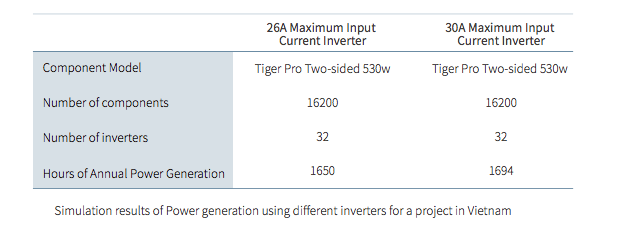

Through numerous experiments, we know that the short-circuit current and working current of bifacial modules are much higher than those of mono-facial modules. At present, the maximum input current of MPPT of mainstream string inverters is 26A, while when the back gain is more than 30%, and the solar irradiance is very good (>1000W/m2), the output current of the modules may be more than 13A. If one MPPT of the inverter connects two groups of strings, the output of the modules will be lost. In order to bring higher power generation and lower power cost to clients, we have been in close communication with several mainstream inverter manufacturers to promote the launch of high current inverter products in response to JinkoSolar’s high performance bifacial modules. We take a location in Vietnam as the research object, import the data into PVsyst for simulation, and obtain the following results:

We can see that the inverters with high input current will be better optimized for the higher power generation of Tiger Pro products.

5. Higher production processes and product quality:

JinkoSolar’s modules have been rated as the most bankable in the industry, largely because of the company’s excellent production processes. In today's 1500V system era, high-quality module products have a lower mismatch rate between groups and modules in long strings, which makes it easier for inverters to track to the maximum power point, especially in power stations that have been running for many years.

In summary, JinkoSolar’s Tiger Pro has advantages in both cost reduction and compatibility on the system side, and this series of products may become one of the mainstream module selections in the new industry.

TÜV Deeply Interpretation

How Does Tiger Pro of JinkoSolar Achieve a Lower LCOE from the Aspect of PV System?

Along with the subsidy-free grid parity policy’s release of National Development and Reform Commission and National Energy Administration, PV module power is upgrading unremittingly to meet the demand of the era of subsidy-free grid parity. With the rapid technology innovation, the diversity of technology type and power class of PV module increases gradually among manufacturers over time. On May 15th, 2020, Jinko Solar launches its latest PV module with 580W maximum power and 21.6% efficiency. It indicates, to some extent, a rise of competition in production capacity and performance of PV module. Most mainstream manufacturers launch their high-efficient modules one after another. Under this circumstance, more and more investors and EPCs pay great attention to high-efficient modules especially after the release of Jinko Solar’s latest product. Therefore, the topic about how high-efficient modules achieve a lower LCOE in PV system will spark a heated discussion on a wide-range power escalation.

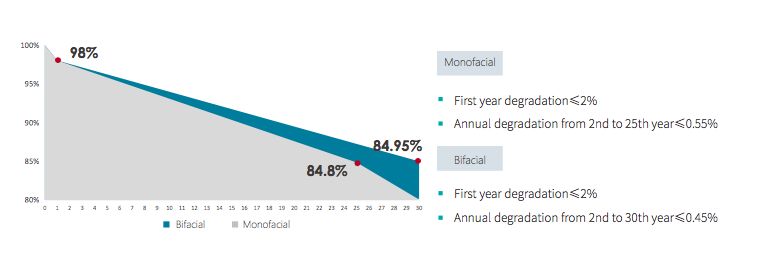

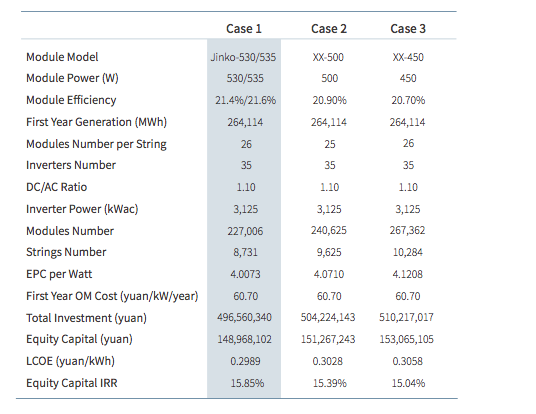

From the perspective of third party, TÜV NORD makes a series of analysis and comparison between high-efficient PV module of Jinko Solar and other two mainstream products. In the report, on the assumed condition of 120MW DC-side project, economic performance of Jinko Solar’s 530W/535W PV module is compared with others from the aspects of technical proposal review and financial income analysis. Regardless of the first-year power generation gain, final revenue will be evaluated to meet the demand of investors and EPCs.

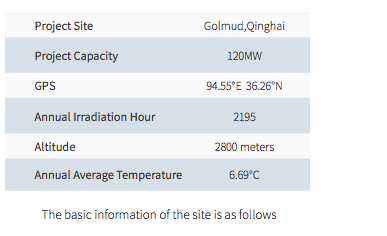

In order to fairly and objectively compare the performance of the three modules applied to the project, TÜV NORD selected and analyzed the same project site as comparison condition. The purpose is to limit the uncertain factors of evaluation results under the conditions of the same geographical location, type of power plant, meteorological conditions, on-grid electricity price, and tax policy. For the convenience of comparison, Golmud in Qinghai is chosen as the project site. The annual irradiation of this area reaches up to 2195 hours, which belongs to the first-class light area in China. The annual temperature is low, average 6.69 degrees centigrade annually. And the ground of PV area is relatively flat.

Combined with TÜV NORD's analogy analysis of existing projects on the market, the initial investment costs of the three module solutions can be estimated and deduced, including the costs of pre-project development, EPC and grid connection. Then, by inputting Jinko 530/535W module’s pan-file into the PV Syst software, the first year’s power generation can be calculated through simulation. At the same time, in order to eliminate the loss of the abandoned light rate and achieve a uniform power generation, we uniformly set the DC/AC ratio as 1.1. In addition, it is also assumed that the 3 cases have the same degradation and OM cost. In conclusion, the results are as follows:

Under the established unified DC capacity, land availability and module price, the case 1 of Jinko 530/535W module has great advantages over case 2 and 3, such as LCOE and IRR, which mainly reflects in the following aspects:

1 / Use of MBB and TR Technologies

Tilling Ribbon, multi-bus bar technology leads to a higher power and higher efficiency. For the all system, higher power module can reduce the number of strings in the condition of same DC/AC ratio. Likewise, the cost of corresponding DC cables, PV mounts, combiner boxes and their installation, even the land of PV will be cut down accordingly. The more efficient module with tracker designed will increase the power generation and reduce the mounting system area. So the cost per watt is decreased, especially for the commonly used 2P tracker.

2 / Lower Module Open-Circuit Voltage (Voc)

In the design, the lower open circuit voltage can increase module numbers per string, which will reduce the number of strings in the system, as well as the corresponding tracker, cables, and installation costs. Thereby the total cost of the project can be cut down.

3 / High Module Quality and Reliability

Jinko Solar is known for its high-level production lines in the industry. The failure rate and dispersion rate of production lines are relatively low, resulting in the low mismatch rate in of 1500V DC part. High-quality and high-reliable module can greatly improve the inverter MPPT tracking efficiency and result, achieving higher inverter’s output.

Auditing from the results of this evaluation, Jinko 530/535W module has certain market competitive advantages technically and economically.