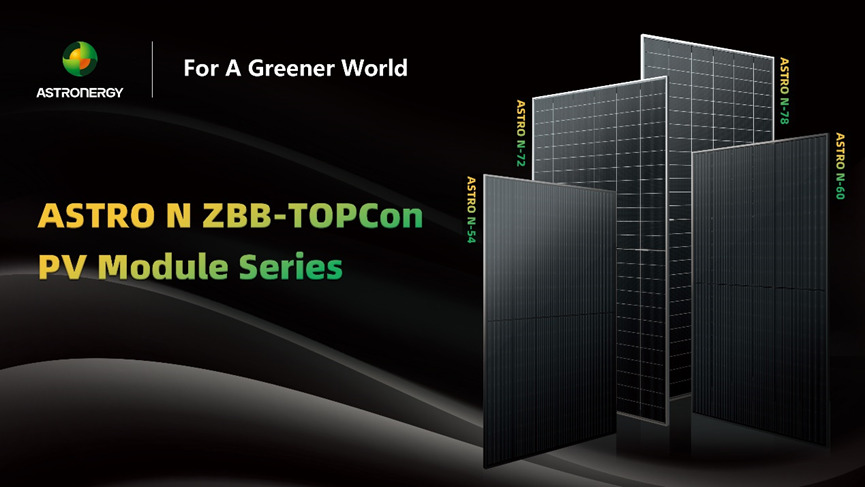

Astronergy has announced the successful roll-out of its ASTRO N 78-cell ZBB-TOPCon modules from its Fuyang manufacturing base, marking the product’s official entry into mass production.

ZBB(Zero BusBar)technology utilizes more and thinner ribbons to replace traditional cell busbars. This design increases the light absorption area of the cell and reduces the risk of hidden cracks, enhancing current collection and improving the reliability of current transmission. Meanwhile, the company’s innovative carrier film has been developed with high bonding adhesion to realize the tight connection between ribbons and cells, the low-temperature manufacturing process effectively reducing internal stresses and providing better performance in terms of mechanical properties, thermal reliability and PID resistance.

The manufacturing process produces no flux or VOC emissions, making the modules more environmentally friendly and, by leveraging ZBB technology and removing pad points and harpoon-like grid lines, their design is more visually appealing.

The transition from small to large-size ZBB-TOPCon modules underlines Astronergy’s commitment to technological innovation, significantly enhancing the adaptability of its products to meet the diverse needs of global clients.

With a production capacity of over 6GW planned in 2024, the company is ready to meet the growing demands of the solar market and continue to supply module products with high efficiency and a guarantee of quality.