1. Abstract

As a product operating for 25 or even 30 years, generating electricity continuously is essential for a PV module to maximize value for customers. Therefore, the module should be designed in consideration of its ability to resist extreme climatic conditions throughout its full life cycle. To verify the ability of a module to resist external mechanical stress, LONGi and TÜV NORD jointly carried out a wind tunnel test to measure its ability under a dynamic load, with LONGi also carrying out a static load test on a large-size module (LONGi Hi-MO 5, 2.26×1.13m) and an oversized module (2.38×1.30m), to simulate bearing capability under an outdoor snow load. The test results showed that the rigidity of both the monofacial and bifacial Hi-MO 5 is better than that of the oversized module and can pass the thresher test at a wind speed of 60 m/s. The static load test showed that the deformation of both the monofacial and bifacial Hi-MO 5 module was less than 45 mm, and their anti-crack abilities were excellent.

2. Dynamic Load Test – Wind Tunnel Test

• Basic test of wind tunnel

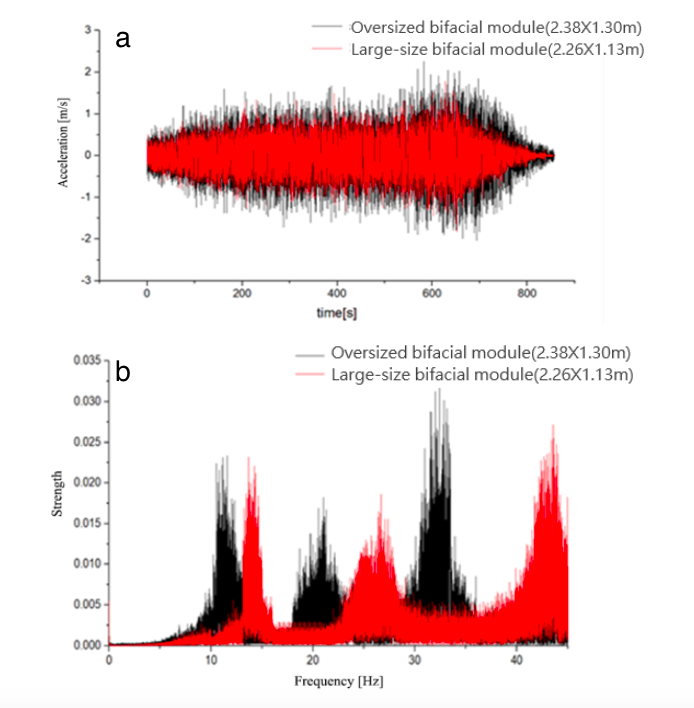

The vibration acceleration and strength of the large-size and oversized modules were tested respectively in the wind tunnel laboratory. It can be seen that the acceleration of the black curve (oversized module) is greater than that of the red curve (large-size module) during the change in wind speed, which further indicates that the vibration amplitude of the oversized module is bigger than that of the large-size module. Therefore, the vibration amplitude of the oversized module will be greater than that of the large-size module in the case of consistent wind speed.

On the other hand, the rigidity of the module is positively correlated with its natural frequency, namely, the lower the natural frequency of the module, the lower its rigidity. The lower rigidity means that lower energy is required for wind-induced vibration of the module under an outdoor wind load, increasing the risk of its failure. As shown in the above figures, the natural frequency of the large-size module is higher than that of the same type of oversized module, so its rigidity is also higher. According to calculation of the rigidity matrix, the structural rigidity of the large-size bifacial module is 1.3 times that of the oversized equivalent. The reliability of the module is based on its rigidity. A reduction in rigidity would cause a decrease in reliability, leading to higher risk for a power plant. This may be resolved by increasing design margin, but the cost of the power plant will then be increased.

• Wind tunnel thresher test

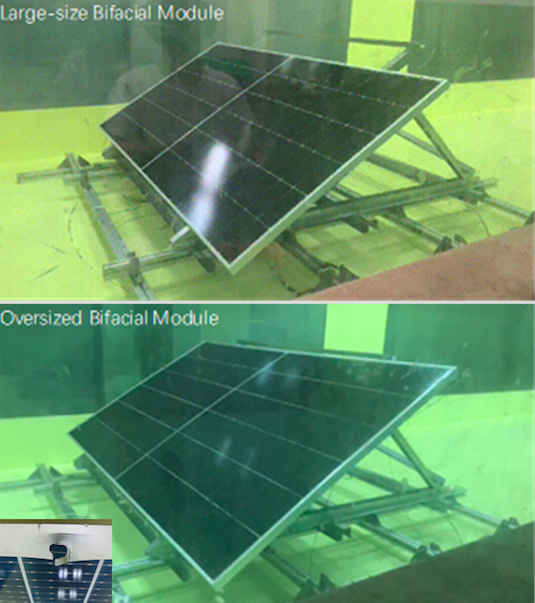

In order to test the characteristics of a module in extreme cases, a further thresher test was carried out, i.e., the wind speed was increased until the module was damaged. Pre-compliance testing was carried out on the wind load capacity of the module, which is different from the static and dynamic load tests in the laboratory in that the reciprocating vibration frequency of the module caused by the wind tunnel test is greater than in laboratory conditions, and the deformation inertia force of the module is found in the tests. (Note: The wind load frequency is lower than the natural frequency of the module, and the resonance does not occur in the module during the test.)

This test showed that when the wind speed is 45 m/s, the oversized module has failed, and the bolted screw hole is deformed and broken. Notes: The limit value of the test does not mean that the failure actually occurs only when the limit value is reached, and the actual parameters such as local gustiness factor and pulse wind conversion also need to be considered; therefore, failure may also occur below hurricane level (32-37 m/s). However, the large-size module can still pass the test when the wind speed is continuously increased to 60 m/s. The above data shows that the performance of the large-size module at extreme wind speed is at least more than 30% better than that of the oversized module.

This wind tunnel test was completed together with the TÜV NORD laboratory and the report on test results has been published.

3. Static load test

• Load capacity of single-glazed module

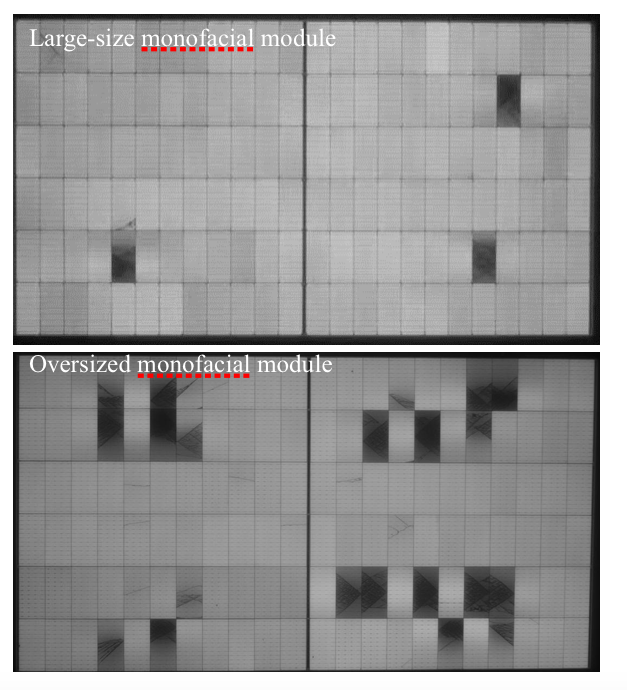

The primary factor that determines the static load capacity of a PV module is glass, followed by the frame. From the perspective of module cost and weight control, the glass thickness of the monofacial module is still kept at 3.2 mm, but its deformation is also increased with the significant increase in its area, thus a greater number of cell cracks affecting power output. In this case, two reinforcing ribs are added on the back of the oversized monofacial module, so as to logically control its deformation under the static load. However, the reinforcing ribs are only helpful for the front load, and deformation still increases when the module is subjected to a negative load. To study the above situation, the static load test was respectively carried out on a large-size monofacial module without reinforcing ribs on its back and an oversized monofacial module with two reinforcing ribs on its back at -2400Pa. The measured deformation of the large-size monofacial module was 43.5 mm, while that of the oversized monofacial module was 67 mm. After testing, the EL image further shows that the number of cracks on the oversized module are 6 times those of the large-size monofacial module. The tests verified that the schematic design of the reinforcing ribs is not helpful for negative wind pressure, and the reinforcing ribs can only help the oversized module meet the IEC test standard for positive pressure (5400 pa).

• Load capacity of bifacial module

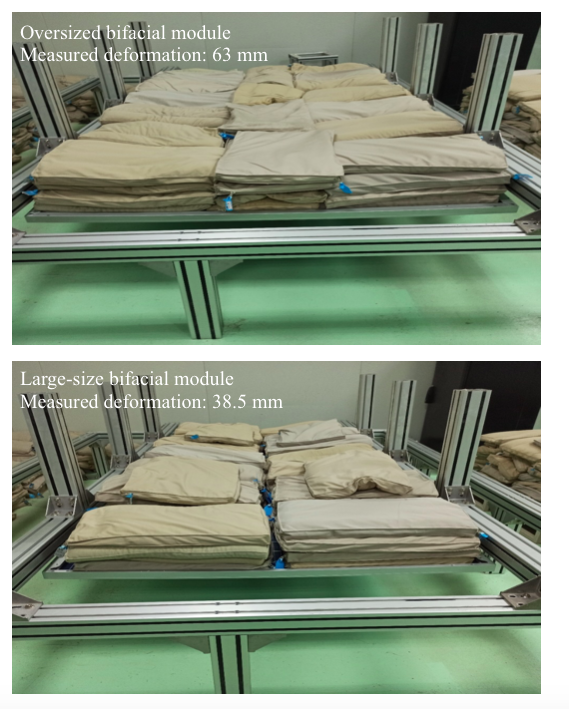

Similar to the static load test of the monofacial module, the static load test (-2400Pa) was also carried out on the large-size and oversized bifacial modules. The test results showed that the deformation of the large-size bifacial module is 38.5 mm, while that of the oversized bifacial module is 63 mm. The figure below shows that the deformation of the oversized module is much larger than that of the large-size module, indicating that Hi-MO 5 has a clearly superior performance against deformation and cracking.

4. Summary

According to the above dynamic and static load tests, Hi-MO 5 has an excellent performance in both rigidity and resistance to extreme wind speed damage, deformation and cracking. The module size of 2.26m*1.13m has been proven to be mature and stable throughout testing, which effectively ensures the reliability of the product. It can cope with “once-in-a-century” hurricanes or blizzards during its life cycle, thereby bringing long-term benefits to customers and ensuring power plant safety.