With solar increasingly establishing itself as the leading source of green energy, the focus is shifting towards the sustainable nature of the equipment and materials used to produce solar modules and the modes of transport chosen to deliver the modules to their ultimate destination. The concept of “product carbon footprint” is key in this regard.

Product carbon footprint refers to the GHG emissions generated throughout the entire product life-cycle, from the extraction of raw materials to the manufacturing process and from distribution to usage and final disposal. In October 2022, Tongwei’s ‘Terra’ shingled panels were awarded carbon footprint certification (ECS) by French organisation Certisolis, confirming that the footprint generated throughout their entire life-cycle satisfied the high standards demanded.

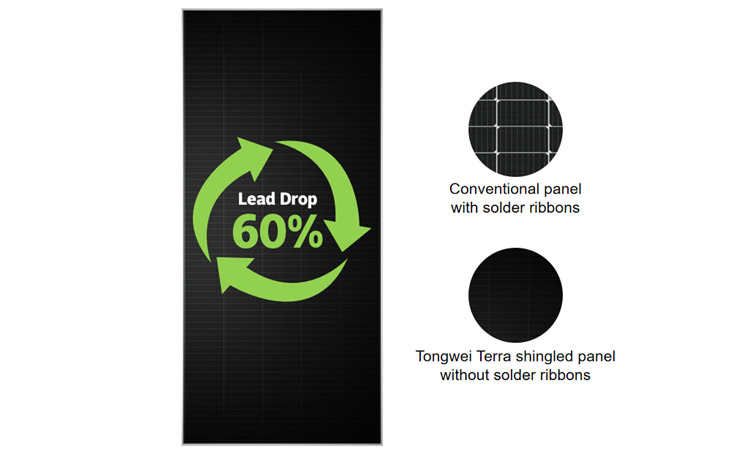

Environmental protection and recycling is a key consideration throughout the R&D process of the Terra series products. Unlike traditional panels, Terra shingled panels adopt an electrically conductive adhesive (ECA) instead of solder ribbons to connect cells, the latter known to be made of heavy metals such as tin and lead, which have a negative effect on the environment. The main film and layer of the Terra panel’s backsheet are also made of fluorine-free materials to reduce long-term pollution.

The flexible adhesive technology enables the panels to adopt thinner cells and be compatible with wafers as thin as 90μm, resulting in 40% lower use of silicon during manufacturing when compared with conventional panels.

In fact, the structure of Tongwei’s entire PV industrial chain, integrating upstream, midstream and downstream, establishes a solid foundation for the company’s ongoing sustainable development.