By Hubert Seigneur, c-Si Feedstock/ Wafering Programme Manager, U.S. PVMC, Florida Solar Energy Center (FSEC), University of Central Florida (UCF); Andrew Rudack, U.S. PVMC, Operations Manager, SEMATECH; Joseph Walters, U.S. PVMC, Programme Director, Florida Solar Energy Center (FSEC), University of Central Florida (UCF); Paul Brooker, U.S. PVMC, Assistant Professor, Florida Solar Energy Center (FSEC), University of Central Florida (UCF); Kristopher Davis, c-Si Programme Manager, U.S. PVMC, Florida Solar Energy Center (FSEC), University of Central Florida (UCF); Winston V. Schoenfeld, Director of c-Si, U.S. PVMC, Director of the Solar Technologies Research, Florida Solar Energy Center (FSEC), University of Central Florida (UCF); Stephan Raithel, Managing Director, SEMI Europe; Shreyes Melkote, Associate Director, Georgia Institute of Technology; Steven Danyluk, Georgia Institute of Technology, Founder and CEO, Polaritek Systems; Thomas Newton, Director of Product Development, Polaritek Systems; Bhushan Sopori, Principal Engineer, National Renewable Energy Laboratory (NREL); Stephen Preece, Director of R&D, Process Research Products; Igor Tarasov, Researcher and Software Developer, Ultrasonic Technologies Inc.; Sergei Ostapenko, President and CEO, Ultrasonic Technologies Inc.; Atul Gupta, Director of Product Development/R&D, Suniva; Gunter Erfu, Managing Director, SolarWorld; Bjoern Seipel, Senior Scientist, SolarWorld; Oliver Naumann, SolarWorld; Ismail Kashkoush, Vice President of Technology, Akrion Systems; Franck Genonceau, Global Product Manager, Solar Products Division, Applied Materials

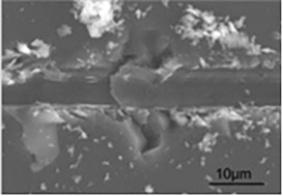

A shift from free-abrasive/steel wire sawing to fixed-abrasive diamond wire sawing is expected to take place in the PV cell manufacturing industry, with 2018 being the anticipated pivotal point for market dominance. This shift is due to several key advantages of diamond wire sawing, such as higher throughput, less wire per wafer, no slurry and the possibility of kerf recycling. However, in order for diamond wire sawing to realize its promise as the next-generation workhorse for the slicing of silicon PV wafers, inherent fundamental challenges must be properly identified and successfully addressed by the PV industry. As a first step to increasing the current collective understanding of the critical needs/challenges of diamond wire sawing, the c-Si programme of the U.S. PVMC held a workshop on July 8th, 2014 in San Francisco, California. One of the key products of this workshop was an extensive list of short- and long-term challenges. This article expands on some of the most important challenges identified at the workshop through the collective discussions and dialogue among a variety of PV industry experts and stakeholders.