By Christian Taubitz, Hanwha Q CELLS GmbH, Bitterfeld-Wolfen, Germany; Matthias Schütze, Hanwha Q CELLS GmbH, Bitterfeld-Wolfen, Germany; Marcel Kröber, Hanwha Q CELLS GmbH, Bitterfeld-Wolfen, Germany; Max B. Koentopp, Hanwha Q CELLS GmbH, Bitterfeld-Wolfen, Germany

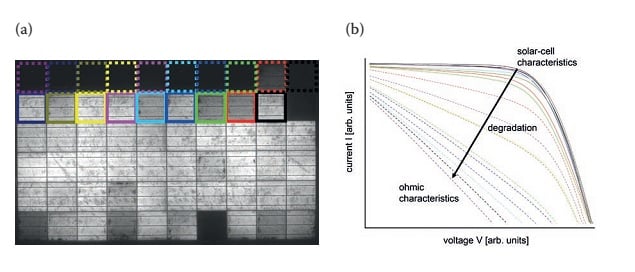

Potential-induced degradation (PID) of the shunting type (PID-s) is one of the most severe forms of PID, which is caused by the negative potential of p-type solar cells with respect to grounded frames/mounting. Although this negative potential can be completely avoided at the system level, that is not the case for a large number of modern PV systems. PV modules that are able to sustain PID-s stress for at least the duration of their service life are therefore essential. To assess whether modules fulfil this requirement, laboratory tests are currently recommended in which the modules are exposed to a certain constant level of PID-s stress for a given amount of time. These types of test with constant stress levels, however, are only feasible in the case of degradation mechanisms that are not reversible in the field, for which non-coherent stress episodes simply sum up to the total stress. Unlike other mechanisms, PID-s is reversible under field conditions; as a consequence, the level of PID-s of a fielded module is the result of an intricate interplay of phases of degradation and regeneration. This behaviour cannot be replicated in a laboratory test using a constant stress level; the currently recommended laboratory tests for PID-s with constant stress levels are therefore not appropriate for assessing the service life duration, and can only be used for differentiating the susceptibility to PID-s stress and for monitoring the stability of production processes. For monitoring the PID-s resistance of its products, Hanwha Q CELLS uses tests for PID-s with constant stress in accordance with the draft for IEC PID test method 62804. This assures that all the products of the Q CELLS brand come with Anti-PID Technology (APT). The expected service life duration with respect to PID-s is assessed by simulating the interplay of degradation and regeneration under non-constant outdoor conditions that are based on meteorological data.