Autowell Technology has partnered with a leading global manufacturer to upgrade over 10GW of HJT production capacity using its 0BB stringer technology.

The upgrade enables the manufacturer’s existing welding + adhesive printing workflow—a common HJT interconnection method—to transition to 0BB technology, a move aimed at reducing silver consumption while maintaining high yield rates, aligning with broader industry efforts to optimize the cost structure of HJT, which faces pressure from silver prices and complex manufacturing workflows.

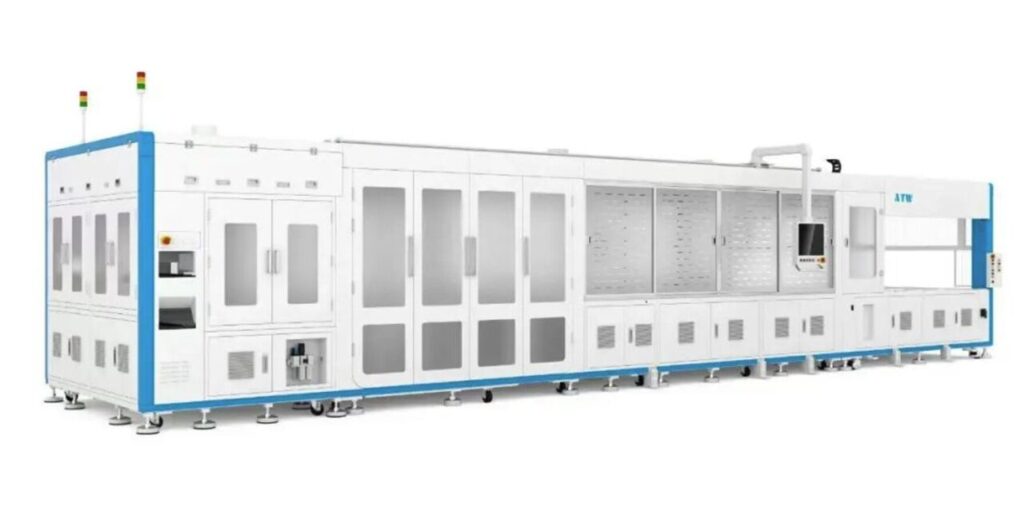

Autowell’s 0BB stringer, developed since 2021 with compatibility for TOPCon, HJT and back-contact (BC) cell technologies, now holds over 120 patents. The company’s high-speed 0BB equipment, commercialized in 2024, supports different temperature controlling processes, accommodating diverse production sequences such as adhesive application followed by curing or welding prior to adhesive application and curing, while supporting multiple adhesive chemistries including UV-curable and epoxy-based systems.

A key feature of Autowell’s solution is its modular retrofit design, enabling manufacturers to upgrade legacy SMBB/MBB stringers to 0BB configurations. This capability allows manufacturers to effectively mitigate the risk of asset stranding due to technological obsolescence and reduce the financial burden associated with full-scale replacement of legacy production systems.

The solar industry’s accelerating transition toward modular, future-ready production strategies is redefining how manufacturers safeguard existing investments. Across global markets, PV companies are increasingly prioritizing adaptable stringer technologies and backward-compatible upgrades—a shift starkly illustrated by Autowell’s 0BB retrofit program and comparable solutions from industry peers. This collective pivot not only mitigates retooling costs during technology migrations, but also underscores the fundamental truth that, in an era of rapid architectural shifts, flexibility is the new currency of sustainable growth.