Introduction

In order to study and verify the power generation and operating temperature performance of different types of modules, JA Solar and TÜV NORD launched a one-year (February 2021-February 2022) energy yield test at the CPVT National Photovoltaic Experimental Base in Yinchuan. The half-year data now being available, the following analyzes the relevant data.

1. Project Information

The field test project is located in Yinchuan, which is typical of a temperate continental climate with an arid environment, with the average annual peak hours being 1650kWh/m2 (horizontal level), average annual sunshine duration 2800 – 3000 hours and an annual average temperature of 8.5 ℃. Yinchuan is one of the regions in China with the highest solar irradiation and a solar spectrum very close to the standard AM1.5. The field test project is shown in Figure 1.

The field test plant is equipped with a set of DeepBlue 3.0 (182mm silicon wafer) monofacial modules and a set of monofacial modules with super-large current (module short-circuit >18A), with an installed power of approx. 7kW (measured by the field test lab) for each set and an inverter of 20kW for both sets (consisting of two-way MPPT input, one way for each set, with maximum input current being 25A). A fixed support structure (with a fixed tilt angle of 40°) is adopted for module installation, about 1 meter above the ground. In addition to the environmental monitoring system, the project is equipped with a double-sided irradiance meter, a high-precision DC meter and a temperature sensor.

To eliminate the effect of inverters on the power generation performance of the different modules, only data from the DC meter is used for the analysis.

2. Comparison of power generation performance

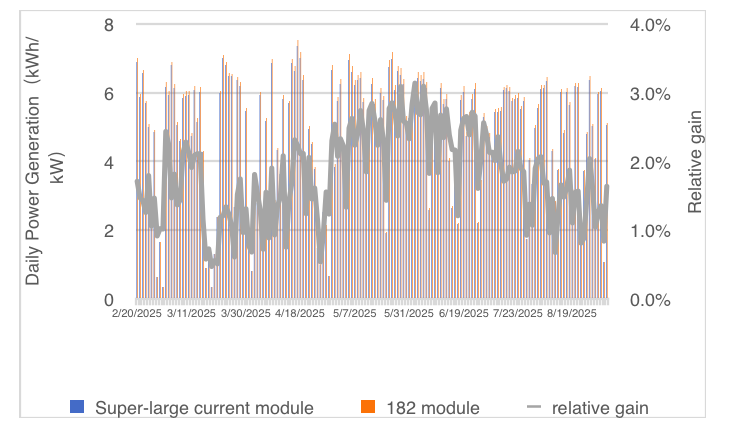

The energy yield performance of JA Solar 182 modules and the super-large current modules between Feb. 2021 and Aug. 2021 is shown in Figure 2. The average daily energy yield of these two module types is 4.88 kWh/kW and 4.79 kWh/kW respectively, with the 182 modules surpassing the super-large current modules by about 1.9%. We can also see that when the irradiation intensity increases (sunny weather, especially from May to July), the energy yield of the 182 modules is 2.5% higher or more than those with super large current. The power generation capacity of PV modules varies with power degradation temperature coefficient, working temperature and power generation performance at a low irradiance level. While both types of modules are based on half-cut p-type PERC mono solar cells, they each have a different operating current according to the difference in wafer sizes. The super-large module employs a 12BB design while the JA Solar 182 module uses an optimized 11BB design. Theoretically, as the internal resistance loss of 182 modules is relatively lower, differences in the power generation performance of the two types of module are caused by the difference in the internal resistance loss and its resulting difference in operating temperature.

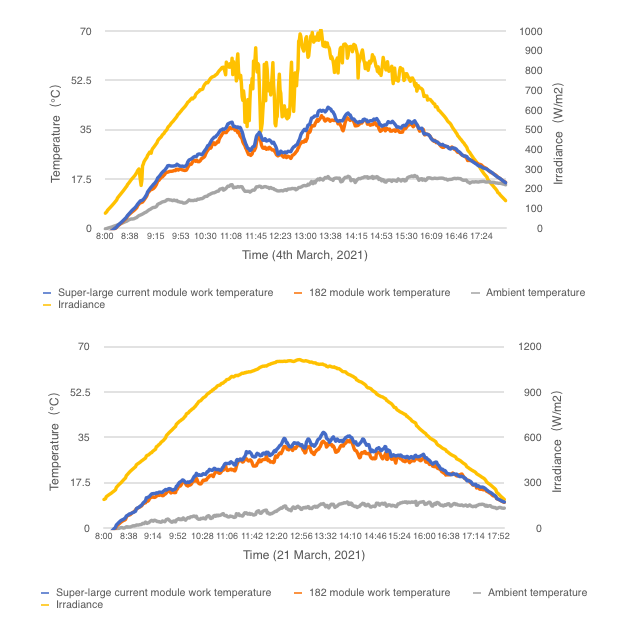

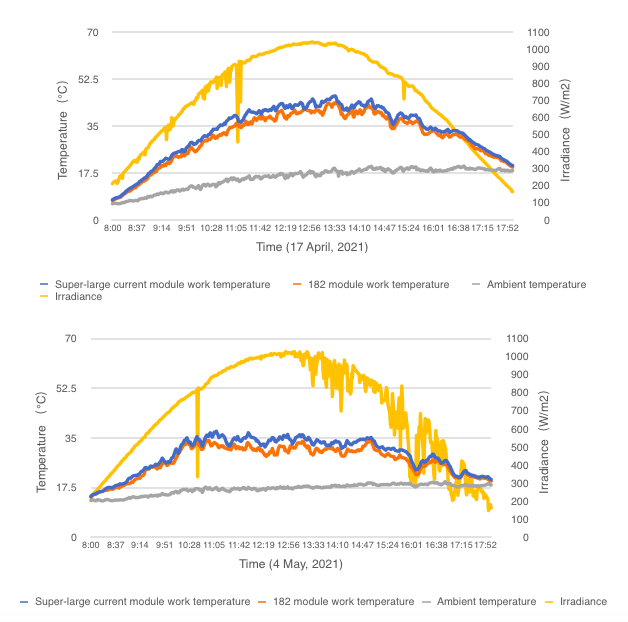

In order to further verify and analyze module operating temperature differences caused by different operating currents, we extracted the operating temperature data and corresponding radiation intensity of the two types of module in sunny and high-irradiance weather. According to the data shown in figure 3, it is clear that the average operating temperature of the 182 module is 1.7 ℃ lower than that of the super large current module, with the maximum temperature difference being 4℃-5℃. When the radiation intensity reduces, both the operating current and temperature of the modules are lowered accordingly, resulting in a smaller difference in operating temperature of the modules with different current levels. Therefore, the difference in operating temperature mainly stems from radiation intensity. This demonstrates that the advantage of the 182 modules in power generation from May to July is due to the widening gap in operating temperature between the two kinds of module. According to theoretical analysis, excessive operating current of a module will cause a significant increase in heat loss on the surface metal contact of the cell, solder zone and bus bar, and the increase in heat loss will lead to a rise in operating temperature, which has also been verified by previous analyses based on operating temperature data of half and full modules.

3. Summary

In summary, during the period between February and August 2021, the power generation capacity of the DeepBlue 3.0 module (based on 182mm wafers) was 1.9% higher than that of the super-large module, due to differences in operating current and internal resistance loss, demonstrating the excellent power generation performance of the DeepBlue 3.0. Testing is ongoing and, once complete analysis of the annual data is ready, this will be made available to both manufacturers and downstream customers.