JA Solar and TÜV Nord have reported the results of a one-year energy yield test carried out at the CPVT National Photovoltaic Experimental Base at Yinchuan. The aim of the test was to study and verify the power generation and operating temperature performance of different types of module.

Between February 2021 and 2022, the two organisations tested the power generation capacity of a JA Solar n-type module, finding it to be 3.9% higher than that of a p-type PERC bifacial module, the test demonstrating the excellent performance of the n-type module, based on Bycium+ cells and n-type passivated contact technology.

The test project was located in Yinchuan, combining a typically temperate continental climate with an arid environment, average annual peak hours being 1650kWh/m2 (horizontal level), average annual sunshine duration 2800-3000 hours and annual average temperature 8.5 degrees Celsius. Yinchuan is one of the regions in China with the most solar radiation and a spectrum very close to the AM1.5 standard.

Figure1: The field test project run by JA Solar and TÜV Nord

The test plant was equipped with a set of n-type bifacial modules, based on Bycium+ cells and n-type passivated contact technology, and a set of bifacial p-type PERC modules, with installed power of approximately 6kW for each set (as measured by the field test lab) and an inverter of 20kW for both sets (consisting of two-way MPPT input, one way for each set, with maximum input current being 25A to ensure no peak clipping in the inverter). A fixed support structure with a tilt angle of 40° was adopted for installing the modules, at a height of about 1 meter above the ground. In addition to the environmental monitoring system, the project was equipped with a double-sided irradiance meter, a high-precision DC meter and a temperature sensor.

For the PV system design and module energy yield analysis, in order to avoid the effect of inverters on the power generation performance of the different modules, only data from the DC meter was used.

Comparison of power generation performance

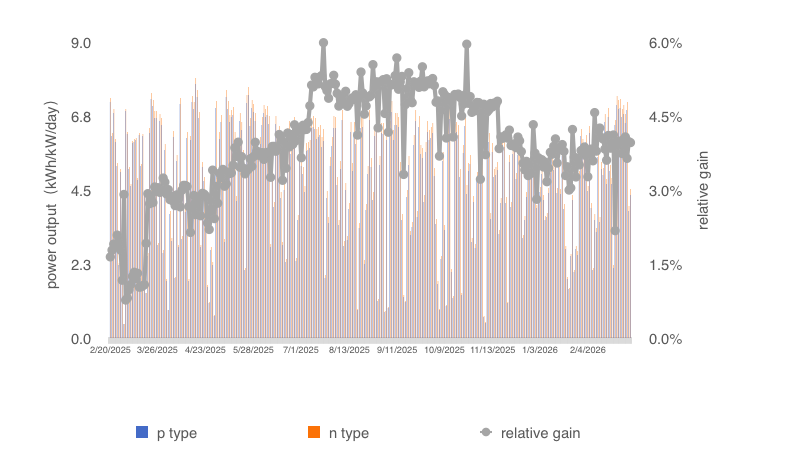

In the full-year test period, the energy yield performance of JA Solar’s n-type modules and the PERC modules are shown in Figure 2. The average daily energy yield of these two module types was 5.03 kWh/kW and 4.84 kWh/kW respectively, the n-type surpassing the PERC by about 3.9%. The power generation capacity of a module depends on power degradation, temperature coefficient, low irradiance performance, operating temperature and bifacial generation performance. While both types of module were based on half-cut bifacial solar cells, the energy yield difference was mainly due to cell technology performance.

In terms of power degradation, due to the natural advantage of an n-type wafer for LID-free and enhanced LeTID performance compared to a conventional PERC cell, JA Solar provides a 30-year linear power output warranty, with less than 1% degradation in the first year and less than 0.4% annual degradation in subsequent years. Calculations show power generation gain in service lifetime to be up to 1.8% and first-year degradation data shows power gain of up to 1%.

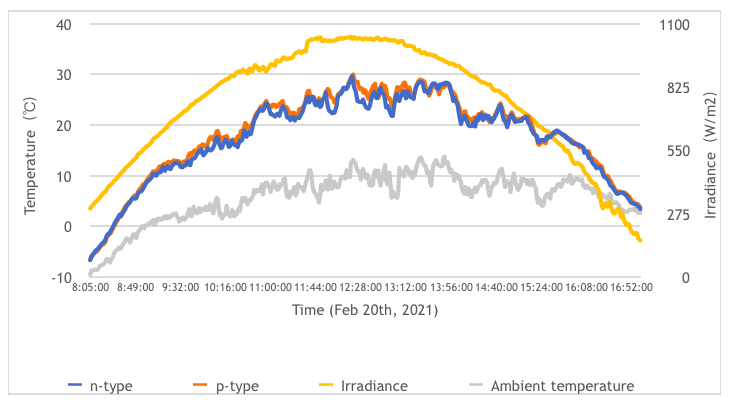

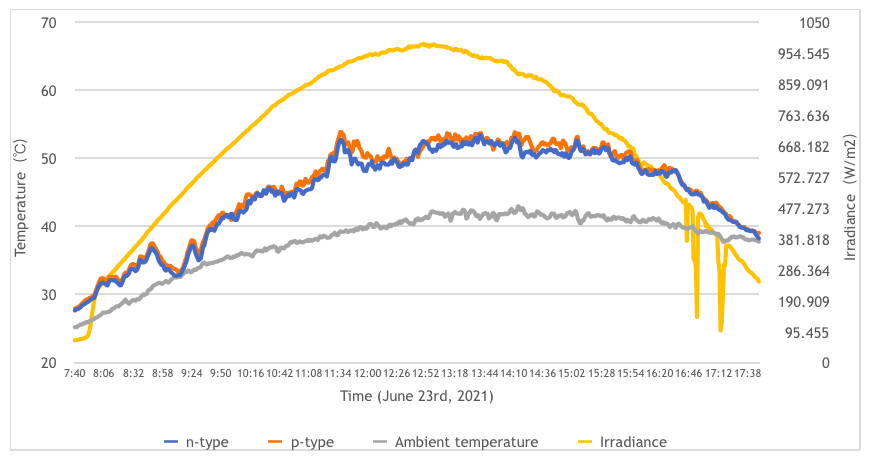

As for high temperature energy yield performance, mainly related to temperature coefficient and module operating temperature, a higher cell open-voltage theoretically results in a better temperature coefficient. The open-circuit voltage of the n-type Bycium+ cell can reach 720mV, with a temperature coefficient of -0.3%/℃, while p-type PERC is -0.35%/℃. During hot weather days, assuming a module operating temperature of 55℃ (ambient temperature 30℃), n-type module power degradation loss is 1% lower than that of a p-type module and, with operating temperature continually increased, the high temperature performance of an n-type module will be significantly better. At the same time, due to the higher conversion efficiency of the n-type module, the heat conversion of the absorbed light energy is correspondingly reduced, thereby lowering the working temperature of the module. The test project fully confirms this, with the average operating temperature of the n-type module about 1°C lower than that of the p-type. Figure 3 illustrates that the power generation of the n-type module is much better in a high temperature environment, where it can be about 2% higher than that of the p-type PERC module.

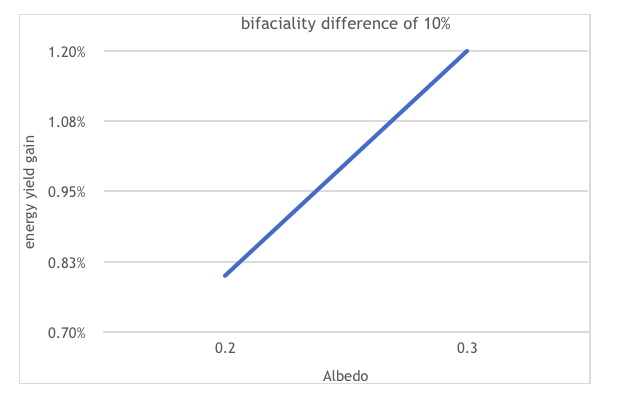

Furthermore, the n-type module has 80% bifaciality, much higher than the PERC module’s 70%. Assuming irradiance on the rear side to be 100~150 W/m2, the 10% bifaciality difference can deliver an n-type module energy gain of 1%~1.5%. Where albedo is 20%~30%, PVsyst simulation indicates a further increase of 0.8%~1.2% in power generation can be derived.

In terms of low irradiance energy yield performance, mainly with a shorter carrier lifetime, open-circuit voltage, sheet resistance and under 600W/m2 conditions such as morning or night fall, simulation shows the n-type energy yield gain to be about 0.2%.