Since Q3 2021, most specialized wafer manufacturers have been mainly focusing on production of large-size wafers, while downstream cell and module manufacturers have been moving forward with the upgrade of their production lines to accommodate the market trend towards large-size, ultra-high-power modules. While the large-size wafer is in line with current market developments, it also presents a greater challenge for existing equipment, especially thermal process equipment, in maintaining the capacity and uniformity of diffusion and coating despite the increase in size – one of the technical difficulties that equipment manufacturers need to overcome.

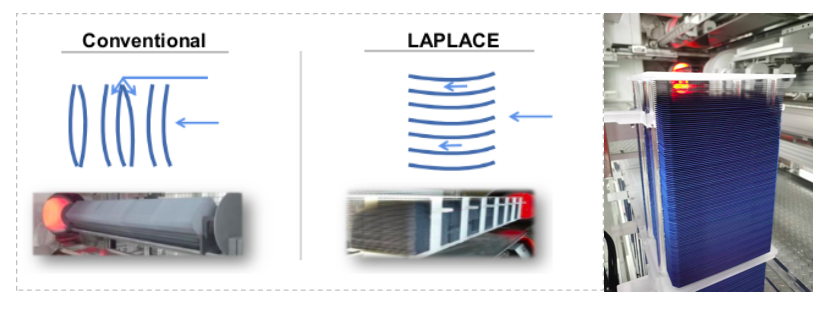

LAPLACE has carried out research into thermal processes and supporting automated equipment for large-size and thin wafers since its establishment in 2016. Based on theory and practice – the transition of semiconductor diffusion from 6″ to 8″ and from vertical to horizontal – LAPLACE has successively introduced horizontal low pressure diffusion (gaseous BCl3 boron diffusion and POCl3 phosphorus diffusion), oxidation and annealing furnaces and horizontal low pressure coating equipment (LPCVD). Low-pressure horizontal placement increases the free range of molecules, reducing gas turbulence and improving diffusion uniformity and stability, especially for large-size wafers and cells. Horizontal wafer placement also has less impact on airflow, allowing air to travel further, resulting in longer effective furnace tubes and greater capacity, increasing machine utilization and ensuring high capacity. The wafers are placed horizontally back-to-back, resulting in a tighter fit and less deformation at high temperatures, reducing winding diffusion.

Based on its horizontal placement platform, LAPLACE has also developed low-pressure horizontal diffusion systems (including boron and phosphorus diffusion, oxidation and annealing), low-pressure chemical vapor deposition and plasma enhanced chemical vapor deposition, all fully validated by customers.