The distributed module market has developed rapidly from the beginning of this year and Trina Solar ‘s 210mm Vertex distributed modules are experiencing strong demand. The following are detailed answers to several questions raised recently.

1. Module selection

Q: Which is the recommended Vertex model for distributed applications?

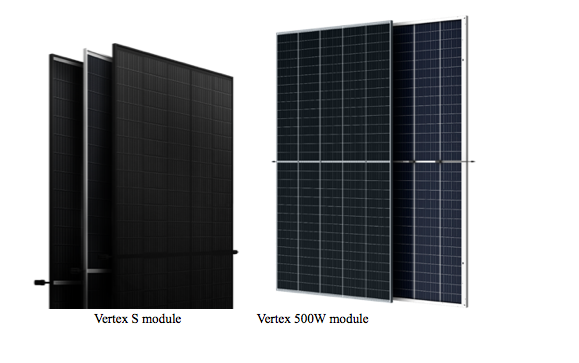

A: Based on the 210mm Vertex technology platform, Trina Solar has developed 400W, 500W, 550W, 600W and 670W options. The 400W and 500W modules are those specifically designed for distributed application scenarios. The former is also known as Vertex S and described as “Small in Size, Big in Power”. There are three types of Vertex S 400W modules: with silver frame, black frame and all-black. There are two types of Vertex 500W modules: single-glass and bifacial dual-glass.

2. Performance & Parameters

Q: What are the specifics of the Vertex 400W/500W series modules in terms of size, weight and efficiency?

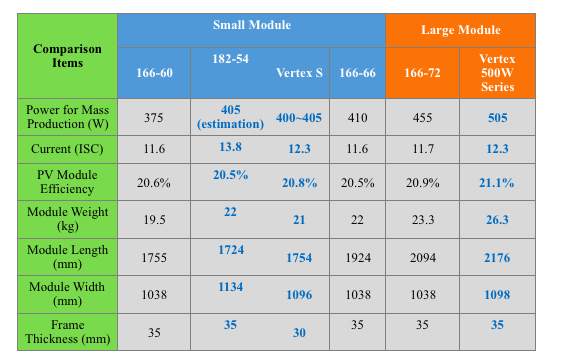

A: The following table shows the specific performance parameters of each and how they compare to conventional 166mm modules. It is clear that Vertex modulesare more efficient. Module current is best optimized with main stream inverters.

3. Efficiency

Q: Why is the Vertex module more efficient than the conventional 166mm module?

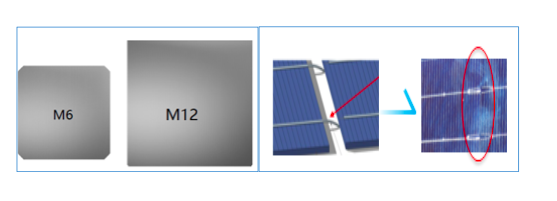

A: The current efficiency of P-type PERC cells is basically the same. The conventional 166mm module uses round-cornered monocrystalline cells, while Trina Solar’s 210mm module uses squarecells with high-density interconnection technology, meaning the gap between cells is narrower. In this way, higher power generation can be achieved within the same area.

4. Large size

Q: Does a 210mm large wafer necessarily mean a large module size?

A: This is a misconception. Large silicon wafers do not automatically mean large size or high current modules. Trina Solar developed the 210mm Vertex 400W/500W series separately for application in distributed scenarios. These two options are based on advanced technologies such as high-density cell interconnection, allowing them to be of similar size to conventional 166-60P (375W) and 166-72P (455W) modules – but with higher power. The Vertex 400W and 500W modules achieve an excellent balance in terms of module size, weight, efficiency and ease of on site installation.

5. The issues with current

Q: Are the Vertex 400W/500W series high-current modules? Can conventional inverters be compatible with them?

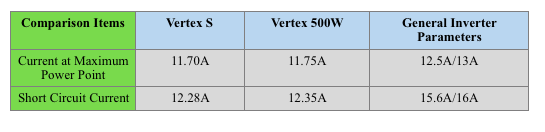

A: No, they are not high current modules.Trina Solar adopts a tri-cut design, dividing 210mm cells into three, which effectively reduces current at the maximum power point. . The current parameters of the two modules are detailed in the following table.

The above table clearly shows that the 210mm Vertex 400W and 500W series modules are both much lower in current than the maximum allowable input value of conventional inverters. Therefore, there is no need to worry about adaptation or compatibility issues, and no need for any upgrades or modifications. Both modules are totally compatible with all mainstream inverters.

6. Logistics and Storage

Q: Can 210mm Vertex 400W/500W series modules reduce logistics and storage costs compared to conventional 166mm modules?

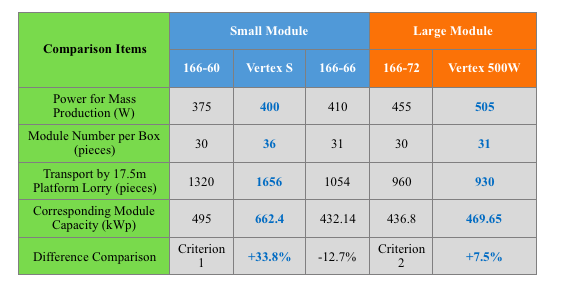

A: The following table shows the comparison of the logistics aspect of 210mm Vertex 400/500W series modules and conventional 166 modules. It is clear that the cost of logistics and storage of 210mm Vertex modules is significantly lower. This provides installers and distributors with significant reductions in transfer and storage costs, reducing crane rental and transfer costs from ground to roof, while also saving time and improving efficiency.

7. Module load capacity

Q: Vertex S modules use a 30mm frame. Is there any risk with load capability? Is the mechanical load performance of a 30mm frame weaker than that of a 35mm one?

A: Module mechanical load compatibility mainly depends on material and frame design, rather than frame dimensions alone. Actually, the optimized design of the Vertex S module’s 30mm frame increases the thickness of the frame and expands the frame cavity to distribute the load bearing, high strength material, meaning that the module’s mechanical load performance is significantly improved. The maximum load on the front side of a Vertex S module can reach 6000Pa, and that on the back side 4000Pa, which is much higher than the respective 5400Pa and 2400Pa with conventional modules.

8. Rack compatibility

Q: Are there any problems with rack installation for 210mm Vertex 400W/500W series modules? Does the 500W series module need 3 beams and 6 briquettes?

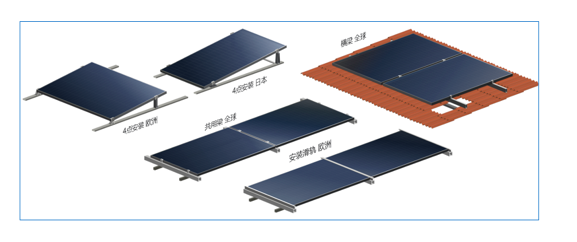

A: The superior mechanical load performance of the two modules has already been mentioned, and there are no additional difficulties with installation compared to conventional modules. They are very easy to install. Therefore, when special mounting methods are used, such as a four-point long edge or a four-point short edge method, a greater load can be supplied and the mounting methods are more varied and convenient. The relevant mounting methods have already been tested in Trina Solar’s laboratory and more flexible project design can be achieved in practice as described in the Trina installation manual. In general, it is not necessary to use 3 beams and 6 briquettes for the 500W series modules. The need for additional clamps to ensure the ability of the modules to withstand load can be determined depending on local meteorological conditions.

9. BOS cost advantages

Q: What are the advantages of 210mm Vertex 400W/500W series modules over conventional 166 modules in terms of BOS cost?

A: As distributed PV power generation gradually enters the subsidy-free era, lower BOS cost and higher power generation are needed to ensure the same returns. The 210mm Vertex 400W/500W series modules have improved module efficiency compared to conventional 166mm modules, which can significantly increase power by 25-50W and achieve higher installed capacity on the same roof area. The increase in installed capacity can significantly reduce the cost per watt of trackers, cables, grid-connected cabinets (boxes) and installation accessories and achieve lower BOS costs. According to calculations by a number of design institutes and installers based on actual cases, the BOS cost reduction delivered by 210mm Vertex modules can reach more than 1 USD cent per watt.

10. Summary of the core value of Vertex modules

Q: How should the core value of 210mm Vertex 400W/500W series modules be summarized?

A: The core values can be summarized as follows:

- Small in size, big in power: Compared with modules of similar size, the power can be significantly increased by 30~60W.

- More installed capacity, more power generation: Higher installed capacity and power generation are achieved on the same roof.

- Lower cost, higher returns: Higher project returns are achieved with lower system costs.

- Strong technology: Based on the Trina Solar Vertex technology platform, many industry-leading technologies have been and will be developed.