By Jonas Bartsch, Fraunhofer ISE; Christian Savio, Fraunhofer ISE; Matthias Hörteis, Fraunhofer ISE; Stefan W. Glunz, Head of the “Silicon Solar Cells – Development and Characterization”, Fraunhofer ISE

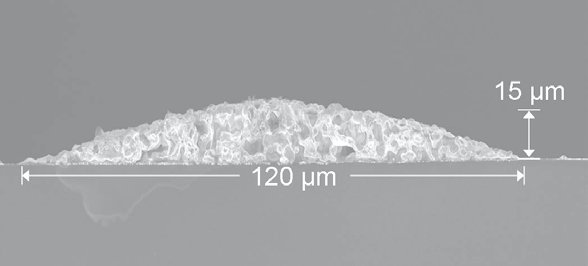

One-step screen-printing processes are still the most widely-used technique for the front-side metallization of crystalline silicon solar cells in the PV industry. This is because of the knowledge, stability and speed of the process, and despite some big disadvantages exhibited by the resulting contacts. Therefore, the metal contacts of high-efficiency laboratory cells are usually produced via advanced two-step metallization processes, which allow the application of optimized contact structures. In a first step, a narrow metal layer is applied to form the contact to the silicon wafer. Several different techniques have been developed for this first stage. In the second step, the seed layer is reinforced electrochemically with a dense layer of a metal of high conductivity, usually by light-induced plating. The transfer of such techniques into industrial scale has been pursued intensively, and may enter solar cell production lines in the near future. However, the process can still be improved based on a better process understanding, in order to benefit from the full potential of the technology.