By Loic Tous, IMEC; Richard Russell, IMEC; Monica Aleman, IMEC; Filip Duerinckx, IMEC; Riet Labie, Silicon Photovoltaics Department, IMEC; Jurgen Bertens, Process Developer, Meco Equipment Engineers BV; Takeshi Horiuchi, Hitachi Chemical Co. Ltd.; Jozef Szlufcik, Director of the Silicon Photovoltaics Department, IMEC

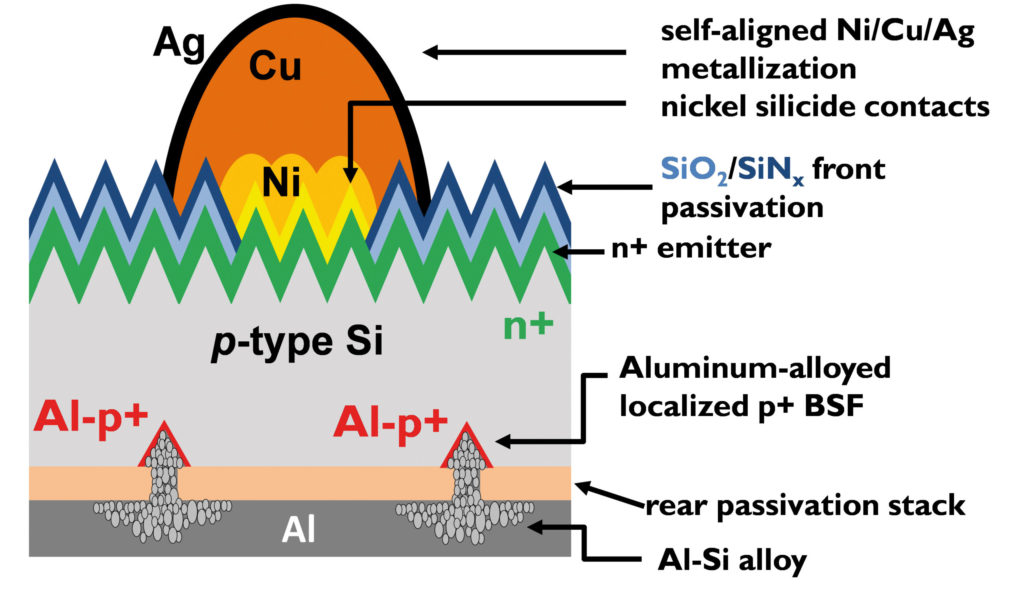

This paper presents the status of imec’s work on the use of copper for the main conductor as an alternative to screen-printed silver front contacts in solar cells. This work is motivated not only by the limitations that Ag screen-printed contacts have regarding solar cell efficiency (high contact shading, limited line conductivity, and poor contact resistance to moderately doped emitters), but also by the PV industry's desire to reduce Ag usage for reasons of cost. Despite the potential advantages of Ni/Cu contacts, their commercialization has been limited because of increased process complexity and doubts over the €/Wp advantage and long-term reliability. These three factors all depend on the specific process and toolset and are discussed in this paper. A relatively simple process sequence is described that uses industrial pilot-line tools and consists of: 1) defining the front-contact pattern by ps-UV laser ablation; 2) self-aligned plating of the contacts using Ni/Cu/Ag; and, finally, 3) sintering in N2 for nickel silicidation. The process sequence is applied to 15.6 x 15.6cm2 p-type CZ-Si PERC (passivated emitter and rear cell) solar cells with 120Ω/sq. homogeneous emitters; average cell efficiencies of 20.5% are achieved over more than 100 cells. Cost analysis results are then discussed, indicating that this Ni/Cu process sequence has a lower cost/piece than equivalent screen-printed PERC cells while also providing ~0.5% abs. higher cell efficiency. Thermal-cycling and damp-heat reliability data that meet extended (1.5 x) IEC 61215 criteria for singlecell laminates and small modules are reported. The improved efficiency potential of applying this metallization sequence to rear-junction n-type PERT (passivated emitter and rear totally diffused) cells is discussed and preliminary results are given.