By Elmar Lohmüller, Fraunhofer ISE; Max Hendrichs, Fraunhofer ISE; Benjamin Thaidigsmann, Fraunhofer ISE; Ulrich Eitner, Fraunhofer ISE; Florian Clement, Head of Group, MWT Solar Cells / Printing Technology, Fraunhofer ISE; Andreas Wolf, Head of the Thermal Processes/Passivated Solar Cells Group, Fraunhofer ISE; Daniel Biro, Fraunhofer ISE; Ralf Preu, Director of the Division for PV Production Technology and Quality Assurance, Fraunhofer ISE

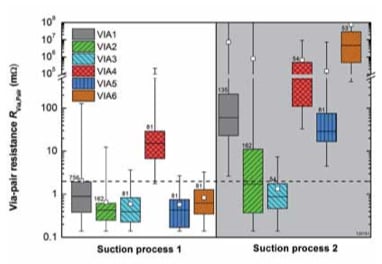

This paper reviews metal wrap through (MWT) solar cell and module technology. As MWT solar cells and modules have received more and more attention in recent years, many highly efficient MWT cell types have been presented by research institutes and industry and are summarized herein. The MWT cell structure benefits from a reduced silver consumption compared with a conventional H-pattern cell, and its realization can be easily combined with novel metallization technologies such as dispensing or stencil printing. The introduction of a rear-surface passivation into the MWT structure is feasible with the high-performance MWT (HIP-MWT) concept developed at Fraunhofer ISE. The resulting fabrication sequence includes only one additional process step – laser drilling of vias – compared with an H-pattern passivated emitter and rear cell (PERC). Furthermore, the synergistic effects of MWT and PERC boost the conversion efficiency gain of MWT-PERC-type cells beyond the expected sum of what could be achieved individually from these two approaches. According to the calculations made by Fraunhofer ISE, conversion efficiencies of up to 21.5% (annealed) are feasible for p-type Cz silicon MWT-PERC cells. Because via metallization is one of the challenges in the fabrication of MWT cells, different via pastes are investigated with regard to their series resistance and contact behaviour. With cell-to-module losses in conversion efficiency of only 0.9% abs., both the interconnector-based MWT module technology and the conductive backsheet concept show promising results.