By Thorsten Dullweber, Cell Production Processes R&D Group Leader, Institute for Solar Energy Research Hamelin (ISFH); Helge Hannebauer, Institute for Solar Energy Research Hamelin (ISFH); Ulrike Baumann, Cell Production Processes R&D Group, Institute for Solar Energy Research Hamelin (ISFH); Tom Falcon, Senior Process Development Specialist, DEK Solar; Rolf Brendel, Scientific Director, Institute for Solar Energy Research Hamelin (ISFH)

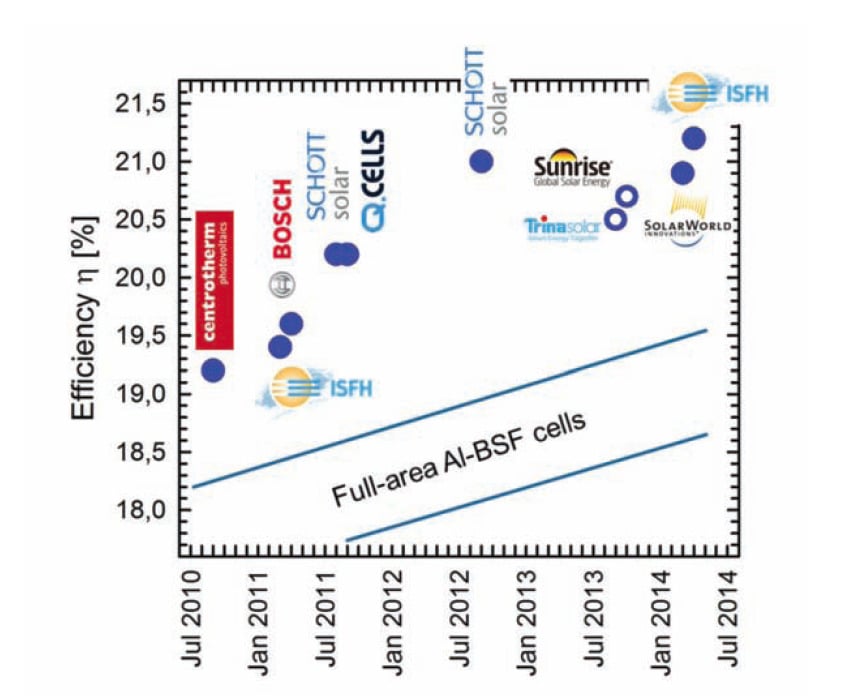

The PV industry is intensively evaluating technologies for further increasing conversion efficiency while maintaining, or even further reducing, production costs. Two promising technologies that meet these objectives are 1) the passivated emitter and rear cell (PERC), which reduces optical and recombination losses of the solar cell's rear side; and 2) multi-busbar/multi-wire module interconnection, which reduces optical and resistive losses of the front grid. This paper evaluates a combination of these two technologies, in particular industrial PERC solar cells with printed metal contacts employing a five-busbar (5BB) front grid instead of the typical three-busbar (3BB) design. The resulting 5BB PERC solar cells demonstrate an independently confirmed conversion efficiency of 21.2%, compared with the 20.6% efficiency for 3BB PERC cells. To the authors' knowledge, a value of 21.2% is the highest reported so far for typical industrial silicon solar cells with printed metal front and rear contacts. The higher conversion efficiency is primarily due to an increased short-circuit current, resulting from the reduced shadowing loss of the 5BB front-grid design, in combination with stencil-printed finger widths of only 46μm.