By Kathrin Reinhardt, Thick-Film Technology and Photovoltaics Group, Fraunhofer IKTS; Markus Eberstein, Manager of the Thick-Film Technology and Photovoltaics Group, Fraunhofer IKTS; Stefan Körner, Thick-Film Technology and Photovoltaics Group, Fraunhofer IKTS; Uwe Partsch, Head of the Hybrid Microsystems Department, Fraunhofer IKTS

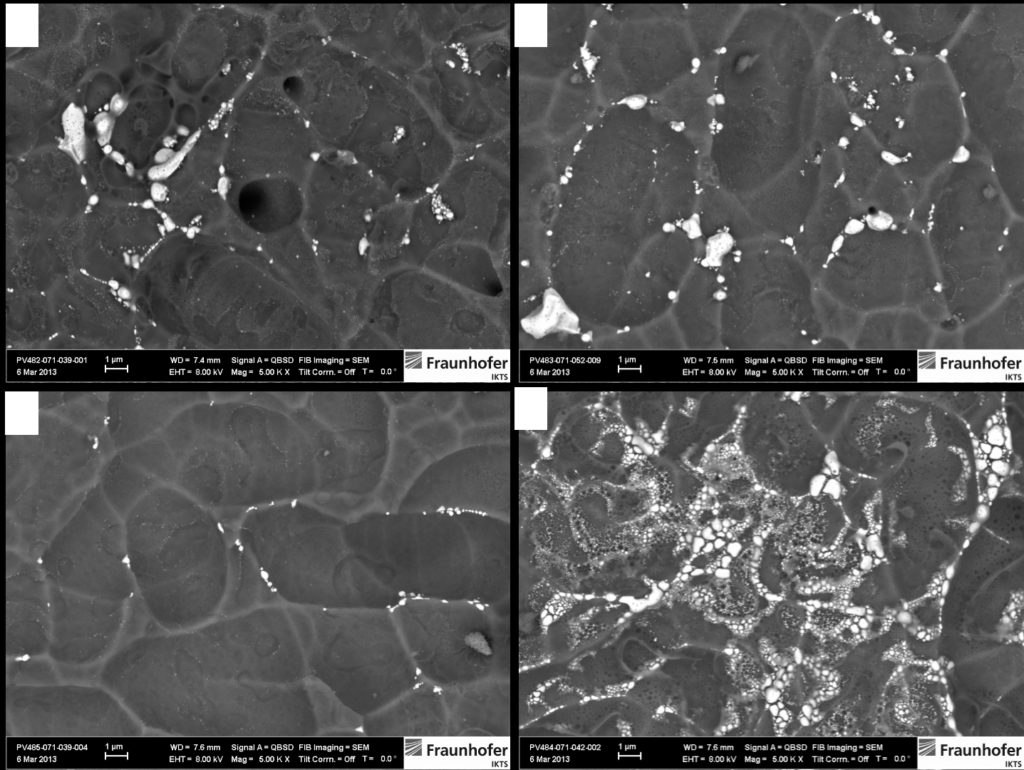

This paper presents the results of a study of the influence of silver powder particle size and inorganic additives on sintering and electrical performance of a PV front-side metallization paste. Three different silver powder grain sizes were used in sample front-side pastes. Also examined is the effect of using four different inorganic additives determined by their redox potential. Solar cells produced using the sample pastes were electrically characterized, and selective etch-backs and FESEM investigations were performed to correlate electrical

performance with the glassy interface between the metallization and the silicon wafer. In the absence of additives, the highest efficiencies were obtained with the medium silver grain size. If the inorganic species has an oxidizing nature, the mass transport of silver in the glass phase can be enhanced. However, the etch process at the wafer surface is also improved by a greater quantity of silver oxide in the flowing glass. It is shown that if the oxidizing capacity of the additive is too powerful, the electrical performance is negatively influenced.

Moreover, the impact of additives is highly dependent on the silver particle size.