By Trond Westgaard, Vice President of Technology, Renewable Energy Corporation; Carol Olson, Project Manager, Energy Research Centre of the Netherlands; Ton Veltkamp, Manager, Crystalline Silicon Photovoltaics Manufacturing Technology Group, Energy Research Centre of the Netherlands

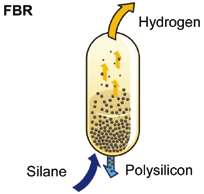

The improved performance and reduced manufacturing costs of photovoltaic (PV) modules that have been achieved in recent years have positioned this technology as an economically attractive renewable electric energy source. In order to verify that this also has a positive impact on energy payback time (EPBT) and carbon footprint, the Energy Research Centre of the Netherlands (ECN) has conducted a life cycle analysis (LCA) for REC Peak Energy-series PV modules produced by Renewable Energy Corporation (REC). The LCA study was based on a full set of actual production data obtained for the first quarter of 2011 from REC’s manufacturing sites. Because REC is an integrated manufacturer, the LCA study includes internal data for the production steps from polysilicon production to module assembly, as well as for all materials and transportation associated with production. ECN used generic figures for installation, operations and recycling together with the REC data to assess the environmental impact indicators. For polysilicon produced in the USA, and for wafers, cells and modules produced in Singapore, an EPBT of 1.2 years was achieved, with a corresponding carbon footprint of 21g CO2-eq/kWh for PV systems located in southern Europe (1700kWh/m2year irradiation). For modules with wafers and cells produced in Norway, the corresponding values were 1.1 years and 18g CO2-eq/kWh. A key contributor in achieving these values is REC’s highly efficient fluidized bed reactor (FBR) process for the production of polysilicon.