By Thibaut Lemoine, General Manager, Senergy Testing Solutions Ltd (STS)

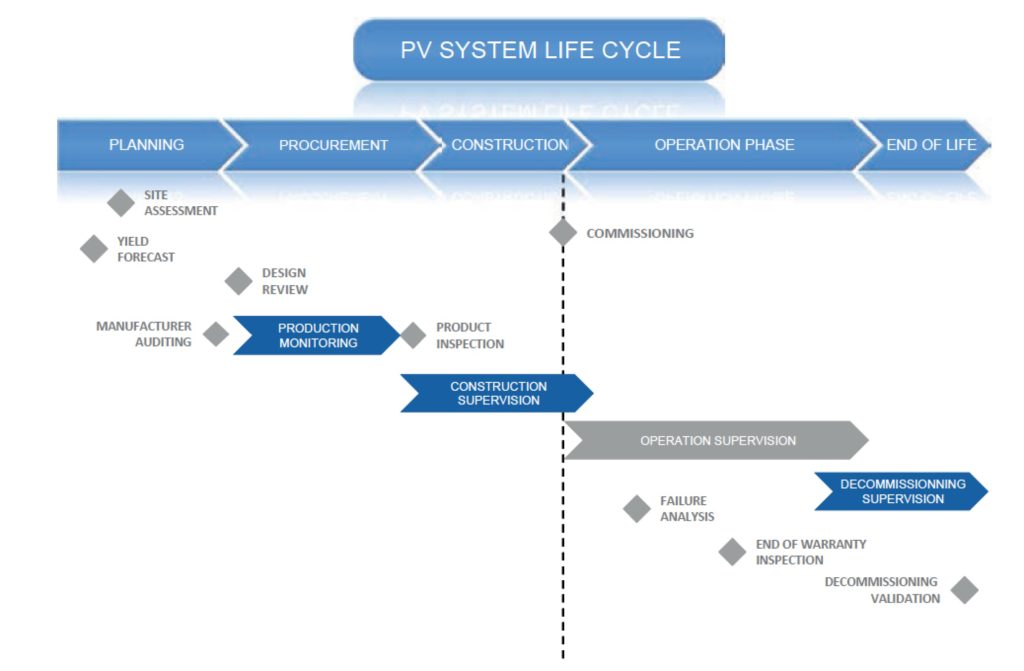

With lower returns on investment in PV projects, financial institutions have an ever-increasing demand for risk mitigation. Project stakeholders are asked to provide evidence of risk-management actions and have to look for ways to guarantee an adequate level of quality for their systems. Product certification, although necessary to help qualify the design of a product, does not provide a guarantee that mass production will achieve the targeted quality level; it has therefore become necessary to find reliable methods to assess the quality of PV systems on a large scale. Production monitoring, as part of a global quality plan for a PV system, is a cost-effective way to implement real-time checks in the manufacturing facilities, providing reassurance for stakeholders and helping manufacturers to improve their manufacturing processes. This paper details the principles behind production monitoring, the methodology used and how to deploy a production-monitoring project.