By Joop van Deelen, TNO, Eindhoven, The Netherlands; Niels van Loon, TNO, Eindhoven, The Netherlands; Marco Barink, TNO, Eindhoven, The Netherlands; Marieke Burghoorn, TNO, Eindhoven, The Netherlands; Zeger Vroon, TNO, Eindhoven, The Netherlands; Zuyd Hogeschool, Heerlen, The Netherlands; Pascal Buskens, TNO, Eindhoven, The Netherlands; DWI – Leibniz Institute for Interactive Materials, Aachen, Germany

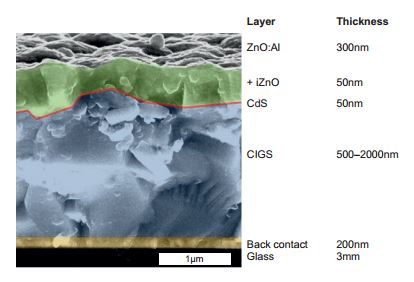

Most development work in the laboratory is dedicated to efficiency enhancements at the cell level; improvements in efficiency can lead to higher cost-competitiveness of PV. However, the cost of panel manufacturing is an important aspect as well. For CIGS panels the deposition of the active layer is an important part of the cost, and decreasing the layer thickness can reduce costs. Moreover, cost of ownership calculations can determine how much benefit can be expected from thinner absorber layers from a cost perspective; clearly, a thinner absorber will result in reduced absorption. To avoid losses, modelling can be used to predict the efficiency and viable light management strategies. Other efficiency-enhancing technology is related to the fact that most thin-film solar panels are monolithically interconnected. The area loss involved in this type of interconnection, and the trade-off between conductivity and transmittance of the front contact, impose limits on the maximum efficiency. The impact of improving both of these aspects is demonstrated in this paper. A viable way to improve the front contact is by supplementing the front contact with a metallic pattern. The benefit and the impact of different configurations and dimensions of the cell and metallic pattern are presented.