By Brad Tinkham; Clement David; Andreas Neumann; Daniel Sixtensson; Thierry Girardeau; Fabien Paumier

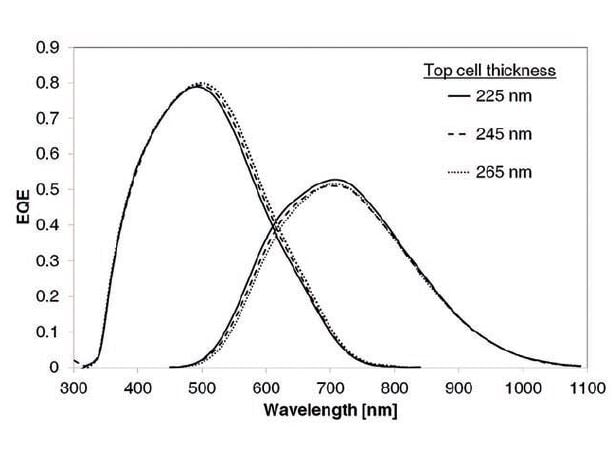

Because of its attractive electronic and optical properties, zinc oxide (ZnO) has found widespread use as a front and back electrode in commercial solar cells. ZnO can be deposited on glass using a variety of different methods, of which vacuum-based techniques are the most commonly used in industrial applications. Aluminium-doped sputtered ZnO:Al (AZO) has been studied intensively for use as a front contact in a-Si/μc-Si tandem cells. The implementation of AZO in series production has been hindered by reproducibility issues stemming from the combination of deposition and subsequent etching steps that are necessary to tune the ‘haze’ of the layers for optimal light scattering. Boron-doped ZnO:B (BZO), deposited by low-pressure chemical vapour deposition (LPCVD), has become a cost-effective option for module manufacturers, since the desired layer morphology can be produced as grown without the need of post-growth chemical etching. This paper addresses the different aspects of using AZO and BZO layers as front contacts for a-Si/μc-Si tandem modules fabricated in series production. The properties of the underlying ZnO layers put restrictions on the layer properties and process parameters that are used in the deposition of a-Si and μc-Si.