By Kay Gastinger, Senior Scientist, Department of Optical Metrology and Data Analysis, SINTEF; Mohammed M'Hamdi, Senior Scientist, Materials and Chemistry, Department of Metallurgy, SINTEF; Trond Bergstrom, Senior Scientist, Materials and Chemistry, Department of Metallurgy, SINTEF; Lars Johnsen, Scientist, Department of Optical Metrology and Data Analysis, SINTEF

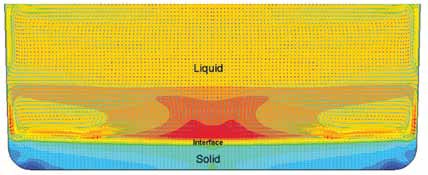

Heat transfer and control of the temperature field are important in the production of silicon solar cell wafers. Present work focuses on the first steps of the production chain, i.e. crystallization and wafering. For the crystallization process, control of heat transfer is crucial for the ingot quality in terms of grain structure, impurity distribution, particle formation, and ingot stresses. Heat transfer is also important during subsequent processes, in particular the wire sawing of the silicon blocks into wafers. The paper emphasises the role of heat transfer and explains the consequences for these processes. Examples from experimental trials and measurements are combined with models and simulation methods.