Romag’s BIPV PowerGlaz technology, introduced in 2004, provides integrated solutions for architects and those involved in the design of PV systems for buildings. The product is designed with the aim of breaking down the aesthetic barrier often in place when considering the use of PV in building design.

PowerGlaz technology has already been installed in many buildings at locations in the UK, Europe and Asia. Some of these BIPV applications include The City Hall, London, BP’s headquarters, Middlesex, and The Solar Sail in Guangdong, China.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

One of the more recent Romag BIPV installations is in the London Borough of Hackney, UK, where PowerGlaz covers the glazed roof of the local Council’s ‘Customer First Centre’. (Pictured throughout) This project’s glass specification presented several challenges, however, Romag’s experience as a glass processor as well as solar PV manufacturer meant that the problems were eventually overcome.

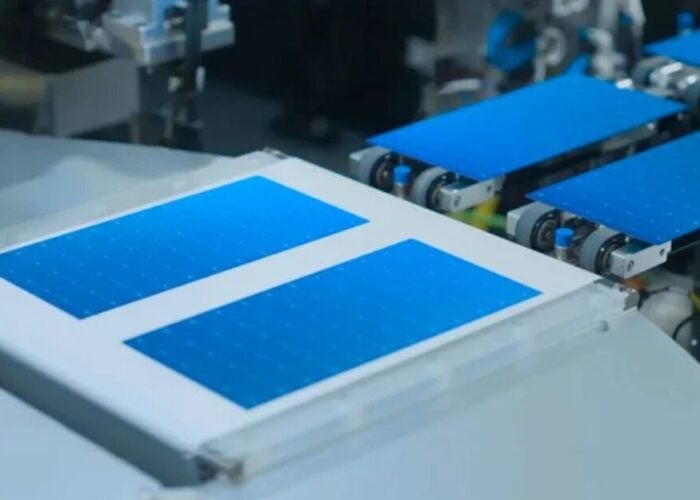

The project involves approximately 600 panels, most of which are insulated glass units. Ninety-six are PowerGlaz BIPV modules and additionally, in areas of ‘shading’, PowerGlaz ‘dummy’ modules were installed. Romag also supplied non-PV screen-printed units; all the PowerGlaz BIPV and non-PV panels meet demanding performance specifications for ‘solar shading’ and insulation. In the case of the PowerGlaz modules the mono-crystalline PV cells were strategically spaced to meet the solar shading requirement.

The project involved argon filled insulated glass units, which also combine low E glass to reduce the U-value and heat loss, structural bonding carrier frames for subsequent structural glazing, using Dow Corning 993 silicone, GP interlayer for enhanced structural performance as well as a combination of heat strengthened, toughened and heat soak tested laminated glass to provide maximum safety and to minimise the risk of ‘spontaneous breakage’ or thermal shock.

Romag processed all the glass for the Hackney project ‘in house’ overcoming logistical issues whilst also enabling phased deliveries to meet the construction programme.