Although growing in prevalence, hail damage to PV modules might not be as worrisome a long-term problem as once feared, write Todd Karin and Tristan Erion-Lorico of PV Evolution Labs.

Over the last few years, the risk of hail damage has topped the list of concerns keeping some solar project developers up at night. Individual storm events have racked up insurance losses in the millions of dollars, with two notable events in Texas each causing over US$50 million in damage. In these specific cases, on-site electroluminescence (EL) imaging determined that cell cracking was responsible for a large amount of the damage sustained by the PV modules. As a result, the insurance market for hail damage tightened, and many project owners have been left struggling to secure suitable coverage. However, recent testing of PV modules by PV Evolution Labs (PVEL) has revealed interesting results, suggesting that the current industry understanding of the effect of cell cracks needs an update.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

Or continue reading this article for free

What are cell cracks?

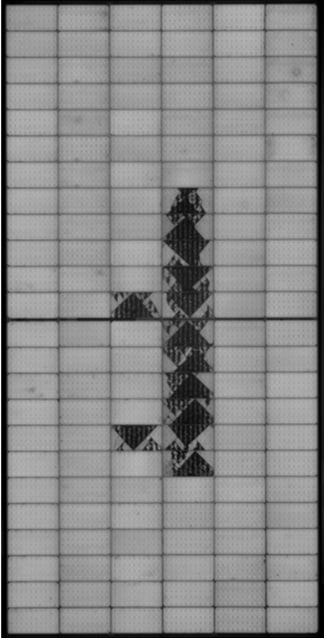

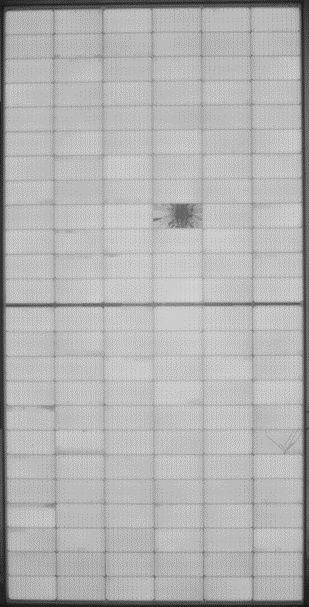

PV cell cracks, also known as microcracks, are defects formed in crystalline PV cells. These can be created by manufacturing defects, such as stresses during cell soldering, lamination pressures, production-line handling, environmental conditions, such as hail or extreme wind events, and other physical damage, such as mishandling during transportation, installation, maintenance, or improper cleaning. Cell cracks appear as dark lines or areas in EL images. Modules with cell cracks produce less energy, especially if these cracks disconnect a region of the cell from the cell interconnections.

In some regions, the severity and frequency of extreme weather events are rising due to climate change, and more gigawatts of solar sites are being located within the likely paths of major storms. Hail, hurricanes, tornadoes and other high-wind events are all known to cause glass and cell cracks in PV modules. In a recent webinar with Brown & Brown Insurance, we reviewed the current state of the hail insurance market and uncovered the good and bad news about cell cracking.

The bad news about cell cracks

The bad news for project developers is that coverage under most hail insurance policies has got worse, often coming with high deductibles or sublimits for hail damage that do not adequately cover the entirety of the project site. For some insurance policies, for modules with cell cracks to be covered after a hail event, more than 25% of the cells must be cracked. Further, the number of affected modules generally must be greater than ~0.5% (for 100MW) to meet the deductible and less than 15% to not hit the sublimit in order to get a significant insurance payout. Outside of those bounds the project owners are on the hook.

This typically means that the days of insurance coverage replacing significant numbers of cell-cracked modules are behind us.

The financials of hail damage

Take a hypothetical example of a utility-scale project with a system cost of US$1.06/W and an internal rate of return (IRR) of 10% over 30 years. The project uses 600W panels that cost US$0.30/W, so US$180/module. Doing some “back of the envelope” calculations, we can assume that each panel generates US$810 of revenue over its lifetime (of course supported by the balance of system). Should these modules become damaged, replacement costs are approximately US$180 for each new module and US$120 for the removal/installation labour and disposal; a total of US$300 per module plus the cost to conduct EL imaging amortised over which modules need to be replaced. In this situation, the replacement is only worthwhile if the replacement cost is less than the cost of the module production value multiplied by the power loss, and the fraction of the site impacted.

Following a hailstorm, project owners now have a choice. Should they just replace modules with broken glass? Or should they also replace the modules with cell cracks? In the above scenario, if a module loses an extreme 50% power due to hail on day 1 of a 30-year project, that module generates US$405 less over the project lifetime, but the EL testing plus replacement cost is likely to be as much or more. This means that while the project will not be profitable, replacing modules would actually make the financials even worse.

The good news about power loss

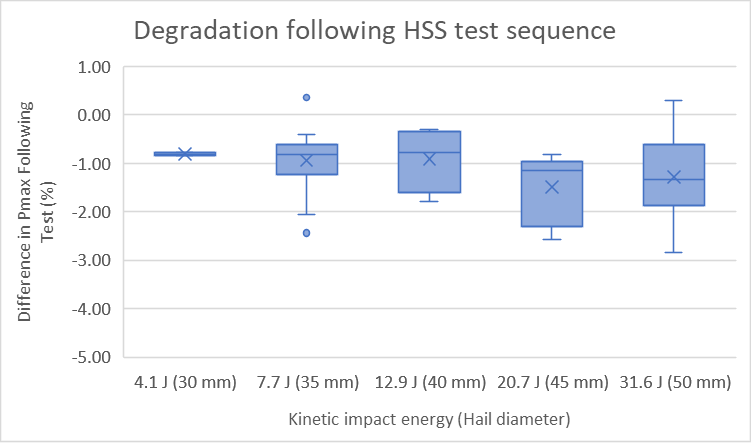

While our test results are often nuanced and difficult to generalise, there is some good news that has emerged: modern modules don’t lose much power even when severely damaged by hail.

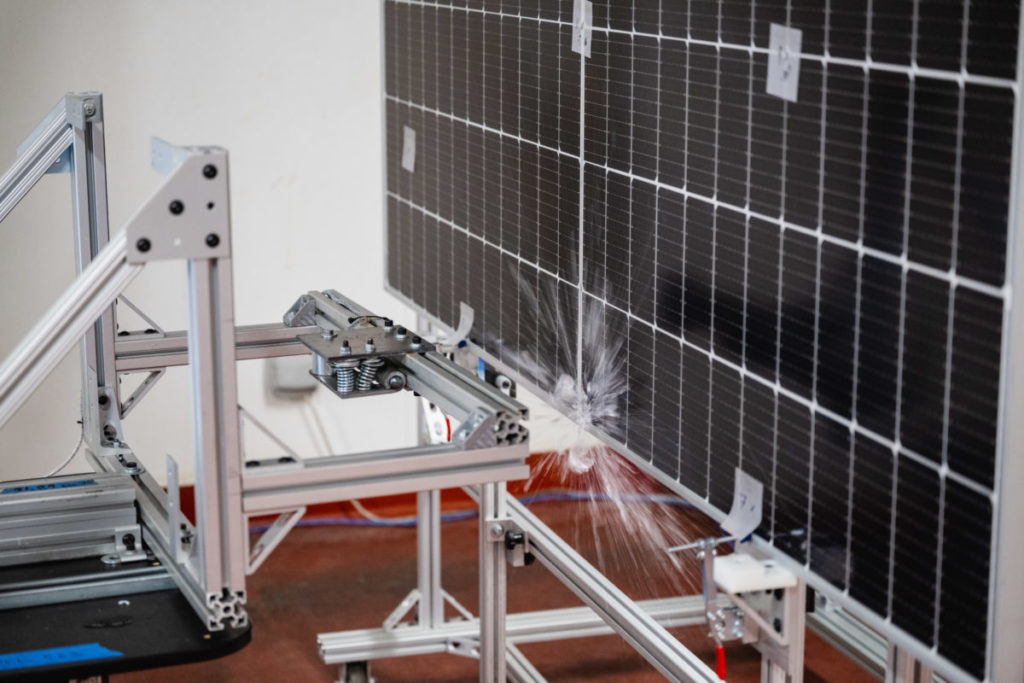

PVEL has analysed the power loss following our hail stress sequence (HSS) over the past few years. This test impacts modules with 11 freezer ice balls up to 50mm in diameter followed by post-hail dynamic mechanical loading and climate chamber testing to stress the cell cracks in susceptible modules, thus reaching their maximum power loss. The results from this testing with regard to power loss are very encouraging.

In looking at our results across technology types, we note that glass-glass modules, which typically suffer higher rates of cracked glass, protect the cells in the neutral plane between the glass layers and, therefore, tend not to experience cell cracking. And while glass-backsheet modules with thicker tempered glass have less glass breakage, their susceptibility to cell cracking-related power loss has also significantly decreased via the use of multi-busbar (MBB) cells. Meanwhile, the industry’s collective concerns regarding cell cracking power loss are often based on studies using older three-busbar (3BB) modules, which are susceptible to higher power loss.

While the cell damage caused by hail and other severe storms may be a cause for concern for some industry stakeholders, the end result is likely not as worrisome as previously feared. PVEL’s testing shows that there are modules that are less prone to glass and cell cracking, and our results should help the insurance industry and others better account for these risks. For sites hit by hailstorms resulting in cell cracks, we would encourage insurance to cover the likely modest amount of power loss overtime rather than module replacement. Annual aerial thermal scans should also be arranged to help identify modules with potential hot spot risks, as those should be replaced preemptively. By following this, insurance should become cheaper for the project owner and more palatable for the insurer.

Todd Karin is VP of technical operations, and Tristan Erion-Lorico is VP of sales and marketing at PVEL.