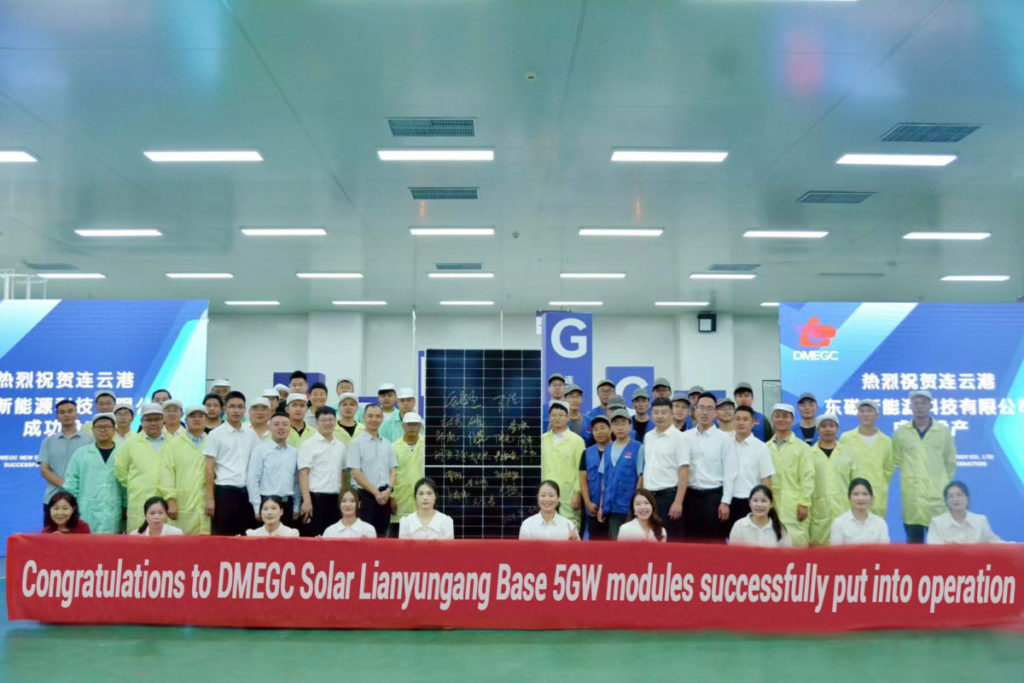

Chinese solar module manufacturer DMEGC Solar has started commercial operations at its new Lianyungang manufacturing base in eastern China, which boasts an annual module production capacity of 5GW.

The plant is the company’s first to be built in the city of Lianyungang, and brings its total annual module production capacity to 12GW. The factory will primarily produce a new type of panel, a bifacial tunnel oxide passivated contact (TOPCon) module that boasts a maximum power output of 630W and a conversion efficiency of 22.54%.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

Or continue reading this article for free

The new module builds on the company’s existing portfolio, such as a 580W n-type bifacial module and a 630W mono-facial module with a conversion efficiency of 22.54%, and DMEGC’s latest product will combine several of the strengths of these modules.

DMEGC also announced that the new facility would form part of its “100% Green Power” initiative, a programme to dramatically improve the environmental performance of solar module manufacturing. The company announced the project in July this year, and plans to use processes such as carbon offsetting and improvements in energy efficiency to ensure that one of its factories produces net-zero emissions by October.

The company also plans to complete what it called “carbon inspections” of all of its factories in early 2024, and noted that it would complete this work alongside German firm TÜV SÜD.

Work such as this could be significant, considering the relatively high carbon cost of producing solar modules compared to the infrastructure required for other renewable energy sources. Figures from the Intergovernmental Panel on Climate Change show that the production of a solar module for use in utility-scale or rooftop environments can generate 41-48g of carbon dioxide equivalent per kWh (gCO2e/kWh) of electricity produced.

While this is significantly lower than the cost of producing coal, with an emission volume of 820gCO2e/kWh, this remains higher than the cost of producing electricity from hydropower sources or onshore wind, with a contribution of 24gCO2e/kWh and 11gCO2e/kWh, respectively. As a result, minimising carbon emissions at utility-scale solar manufacturing facilities could be vital to the long-term health of the sector.

The news follows Trina Solar’s start of manufacturing its latest module, a 700W panel with a conversion efficiency of 22.5%. The Solar Module Super League member is the first company to begin commercial production of a module of such a power capacity, and the latest news from DMEGC demonstrates how solar manufacturers across the sector are looking to ramp up module production to meet the world’s growing demand for solar panels.