China-based PV module materials and N-type mono and IBC (Interdigitated Back Contact) bifacial module manufacturer Jolywood is partnering with European research and innovation hub centre, imec to bring to market an industrialized bifacial solar cells with an average front-side conversion efficiency up to 21.9%.

Currently, Jolywood (Taizhou) Solar Technology Co’s solar cell production is focused on n-PERT cells, ahead of volume ramping of IBC cells.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

As part of the collaboration with imec, the R&D centre was said to have demonstrated screen-printed monofacial n-PERT cells with the conversion efficiency up to 22.8%.

“Jolywood is at the forefront of the n-type industrial technological developments in the PV industry, so we're very satisfied with the close collaboration with Imec, the world-leading PV research institution,” said Dr. Zhifeng Liu, R&D Director of Jolywood. “And we're very delighted with the excellent progress in the development of the high-efficiency bifacial n-PERT solar cells that have come as part of our collaboration. With our strong commercialization capabilities and experience, we look forward to transferring the achievements into commercial production.”

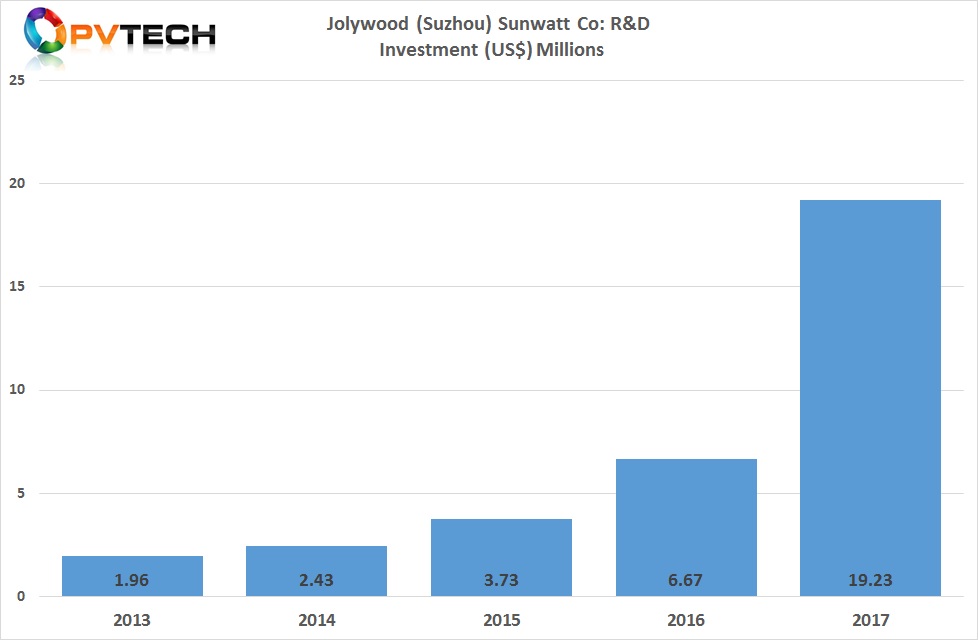

Jolywood has significantly increased its cell and module R&D activities since moving into the market. According to PV Tech’s annual R&D analysis report, Jollywood spent US$6.6 million on all R&D activities in 2016, increasing to US$19.23 million in 2017.

The company noted that the new bifacial cells developed with imec use narrow (~40 μm) printed silver (Ag) fingers on the front side and printed aluminium (Al) fingers on the rear, the latter making contact with the emitter. By using Al instead of AgAl for the rear contacts, the cost per cell was lowered to US$0.01/Wp.

Jolywood also noted that in respect to a batch of M2-sized cells (area: 244.3 cm²), an average conversion efficiency of 21.9% had been demonstrated, with the best cell processed reaching 22.1%.

The company claimed that the solar cells when used in bifacial applications under standard front illumination conditions and in conjunction with an additional 0.15 sun rear illumination, could achieve efficiencies of 25%.