MacDermid’s HELIOS nickel, copper, and silver wet chemical plating baths, which are a key part of an integrated laser patterning, plating, and thermal anneal system, produces 30µm fingers and 4N pull strengths, while reducing costs by US$0.06/cell.

Problem

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

As the cost of producing silicon solar cells has decreased by US$3/Wp since 2008, the demand for PV has grown 40% CAGR, putting pressure on whether conventional screen-printed silver paste can continue to serve the industry’s future needs. In addition, printing and sintering silver limits the ability to implement thinner wafers and more efficient cell designs, due to physical and thermal stresses. To address these challenges, PV roadmaps call for copper grid conductors. Until now, copper conductors suffered adhesion loss, plated on the ARC, and required huge, expensive plating equipment.

Solution

Narrow copper conductors, allowing 50% more light capture, are formed in a 3 step process. A pico second UV laser ablates the ARC, exposing the silicon. An inline, conveyorized plating tool deposits 1µm of nickel, 10-15µm of copper, and 0.2µm of silver, using ultra-fast electrodeposition based on innovative formulae. The HELIOS metal grid is quickly annealed, achieving adhesion similar to paste printed conductors. The nickel achieves a full-area contact to silicon, and the copper reaches conductivity unachievable with paste. Low temperature processing enables all high efficiency cell types, especially PERC, silicon heterojunction, and bi-facial designs. Conductor material costs are immediately reduced 50%, providing a 1 year return on investment. To assure reliability, HELIOS conductors were used on production-scale modules tested at Fraunhofer ISE to IEC specifications. The modules exceeded damp heat and thermal cycle stresses, with no failure after 600 thermal stress cycles.

Applications

Mono and multicrystalline silicon cell conductor formation.

Platform

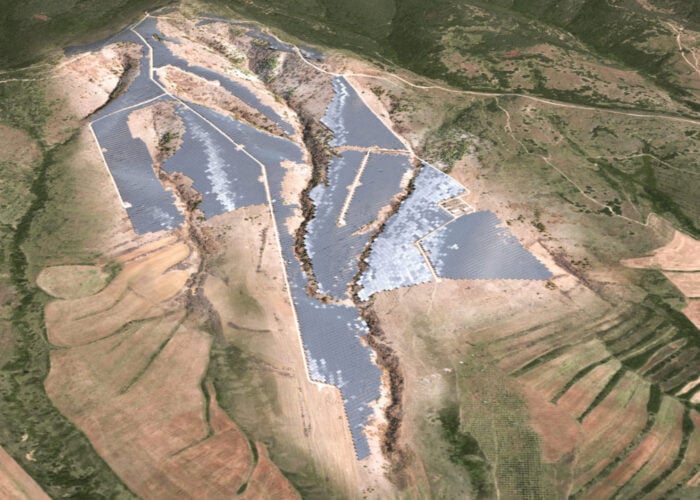

Specialized laser patterning is available from our partner in Germany, scaleable to 50 or 100MW installations, with built-in transport. Conductors are plated using MacDermid’s new HELIOS chemical systems, at extremely high deposition rates, very high purity, and virtually zero plated stress. Most cells will benefit from horizontal, LIP plating tools with single-sided chemical exposure, and unique brush contact, at 20m length for 100MW. Some designs will require vertical continuous plating to achieve fast, double-sided deposition.

Availability

Currently available