DuPont Performance Polymers has tailored its portfolio of thermoplastic materials and design knowledge to the needs of the photovoltaic industry, including the CPV and CSP sector. DuPont has developed two specific grades of ‘DuPont Rynite’ polyethylene terephtalate (PET) that are claimed to reduce the total cost of manufacturing, assembling and installing photovoltaic systems.

Problem

In the case of CPV, modules require a housing material that withstands long-term weatherability issues and yet can be used in multiple design configurations, while lowering processing and material costs in manufacturing. Due to metal price volatility, alternative material choices that can replace such components as die-cast metals and thermosets in applications where stiffness and impact strength are required can become more cost effective.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

Solution

When used in photovoltaic applications, DuPont’s polymers are claimed to help increase design flexibility for greater ease of assembly and installation; provide an opportunity for functional integration (thereby reducing the overall number of components); and when produced in large numbers, offer cost-competitive methods of production through injection molding and extrusion. High performance thermoplastics such as Rynite can offer a high degree of stiffness for structural strength, improved outdoor performance, high impact resistance, corrosion resistance and good aesthetics. By using Rynite PET for frames, resistance to ultraviolet rays, heat, wind and significant loads of snow is assured, as well as enhanced durability and a high surface finish. Two specific grades are currently available from DuPont for cost-effective manufacturing of photovoltaic module frames and components. Rynite 935SUV is a 35% glass-fiber/mineral reinforced, UV stabilized grade of polyethylene terephtalate (PET) suitable for injection molding; Rynite 540SUV is a 40% glass-fiber reinforced, UV stabilized grade of PET suitable for extrusion and injection molding. Both grades combine high stiffness with low warpage and have been specifically developed for long-term outdoor applications.

Applications

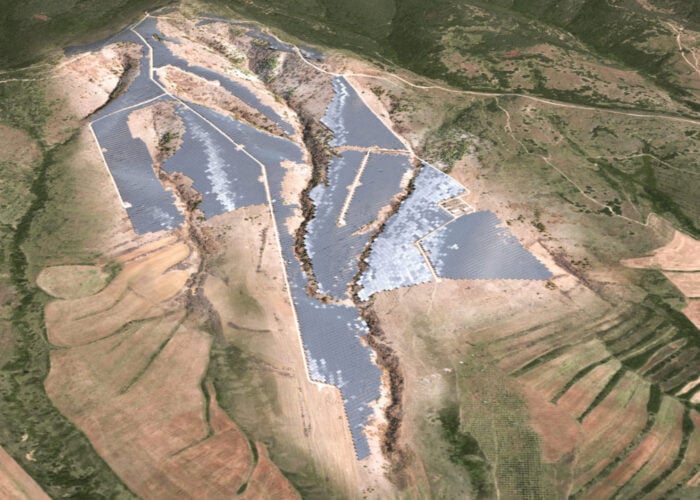

Frames, inverters, connectors and junction boxes as well as for bearings used in sun-tracking mirror installations.

Platform

Other DuPont engineering polymers for the photovoltaic sector include flame-retardant DuPont ‘Zytel’ nylon for junction boxes and inverters, and low-wear/low-friction DuPont Delrin 500 TL acetal resin is used for a Concentrating Solar Power (CSP) bearing, which helps the curved mirrors to follow the movement of the sun throughout the day.

Availability

October 2010 onwards.