Product Briefing Outline: Kemper has extended its family of dual-axis tracking system for photovoltaic (PV) modules, and includes a larger ‘KemTrack’ 120 system, capable of handling a combined module area of 120 square meters. The construction is torsion-free, extremely robust and durable and modular in construction.

Problem: Larger and therefore more efficient tracking systems are required to operate in a wide range of applications, whether due to limited ground space or requirements to maximize output of a given ground-mounted PV project. The ability to handle high winds and snow loadings also requires a sturdy and long-lasting structure.

Unlock unlimited access for 12 whole months of distinctive global analysis

Photovoltaics International is now included.

- Regular insight and analysis of the industry’s biggest developments

- In-depth interviews with the industry’s leading figures

- Unlimited digital access to the PV Tech Power journal catalogue

- Unlimited digital access to the Photovoltaics International journal catalogue

- Access to more than 1,000 technical papers

- Discounts on Solar Media’s portfolio of events, in-person and virtual

Solution: The KemTrack 120 dual-axis tracking system handles more modules compared to its other systems. A current yield of about 17kWp per tracker is claimed compared to 8.6 kWp for its KemTrack 60 system. The tracking system can be transported easily saving space and very economically transported with standard containers in the shortest time worldwide. Optionally the frame construction can be also welded and supplied premounted. The industrial drives used are “made in Germany,” maintenance free and extremely stable. The astronomical regulation of the two drives contains innovative functions and provides an increase of the current efficiency of up to 40%, according to the company. Software algorithms prevent mutual shading with sun exposure angles.

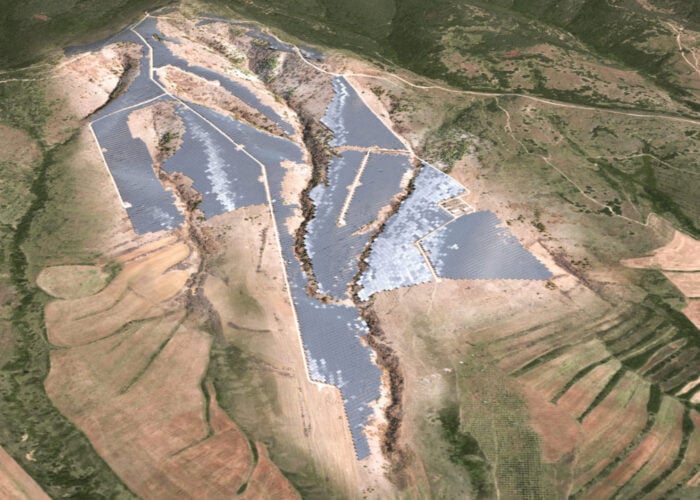

Applications: Large solar farm projects. Project specific individual constructions are possible.

Platform: Torsion-free, hot-dip galvanised steel construction that is suitable for all wind and snow loads adhering to DIN 1055. Extremely high wind protection position can be individually configured. The system has durable and industry tested drives. The central control unit can accommodate modular extensions such as a surge protector or the emergency power supply using batteries including an online evaluation of the charge states can be made.

Availability: April 2010 onwards.