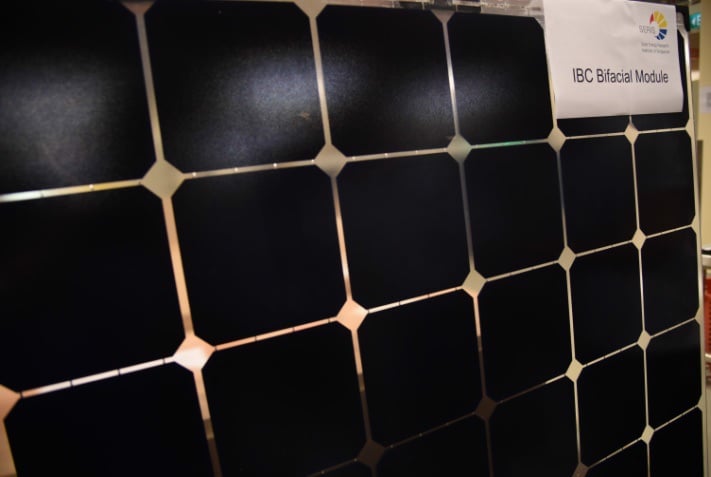

The Solar Energy Research Institute of Singapore (SERIS) at the National University of Singapore (NUS) has developed the world’s first full-sized Interdigitated Back Contact (IBC) bifacial solar module using International Solar Energy Research Center (ISC) Konstanz, ‘ZEBRA’ solar cells.

The 60-cell bifacial module uses 6-inch N-type mono wafers with ISC Konstanz fabricated ZEBRA cells with conversion efficiencies of up to 22%. The module could produce as much as 30% extra power than an equivalent conventional IBC module, due to the bifacial nature of the solar cells and the layout with a double glass structure to ensure ground-reflected light capture. The module was claimed to have a bifaciality of 75% and capable of producing up to 400 Watts.

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

Dr Wang Yan, Director of SERIS’ PV Module Cluster said, “With SERIS’ new module design, panels with 350 Watts front-side power can be made with sixty 23% efficient screen-printed IBC cells. Considering an additional 20% of power via the panel’s transparent rear surface, each 60-cell IBC bifacial module will produce a stunning 400 Watts of power in the real world.”

Dr Radovan Kopecek, founder of ISC Konstanz, Director of Advanced Solar Cells and Lead Scientist for ZEBRA development since 2009, added, “Many people now might think that putting highly efficient IBC cells into bifacial modules does not make sense – but our consortium will prove them wrong. The ZEBRA process is extremely simple and cost-effective and so is the module manufacturing process. In large bifacial systems, this technology will lead to the lowest LCOEs ever. Bifaciality is quickly gaining popularity and, since a few weeks ago, one can also simulate the bifacial advantage using PVsyst – such developments will give many bifacial technologies the breakthrough in the PV systems arena.”

A key driver for bifacial module LCOE competitiveness with conventional modules is the double-glass structure that could offer a longer warranty period of 30 years or more, while generating more electricity of the lifetime of the module.

Prof Armin Aberle, SERIS CEO noted, “IBC cells are famous for their efficiency, reliability and durability in the field. The newly developed IBC bifacial module is a testimony of SERIS’ R&D capabilities in the PV module technology sector. The module technology offers world-class front side power while providing free extra power from the rear side. As a result, it has excellent LCOE potential. The prototype module made at SERIS serves as a proof of concept for mass production. The next step will be to transfer the technology to industrial partners.”

Bifacial modules in general also have the potential to provide the lowest LCOE when used with high albedo flat roofs, chalk/light stone ground surfaces and floating solar systems using white composite float structures. Benefits also exist for carports over conventional modules.

SERIS said that the new IBC bifacial module would be displayed on the booths of its industry collaborators, which include centrotherm photovoltaics AG (booth #360, E3) and SPIC Xi’an Solar Power (booth #330, W1).

Concurrently, Dr. Wang Yan will also report on the IBC bifacial module design at the SNEC conference during his talk on 19th April at the Pudong Ballroom at 1 pm (CST).

Dr Radovan Kopecek co-authored a technical white paper on the status of bifacial PV in the recently published Volume 35 of PV Tech’s sister technical journal, Photovoltaics International.