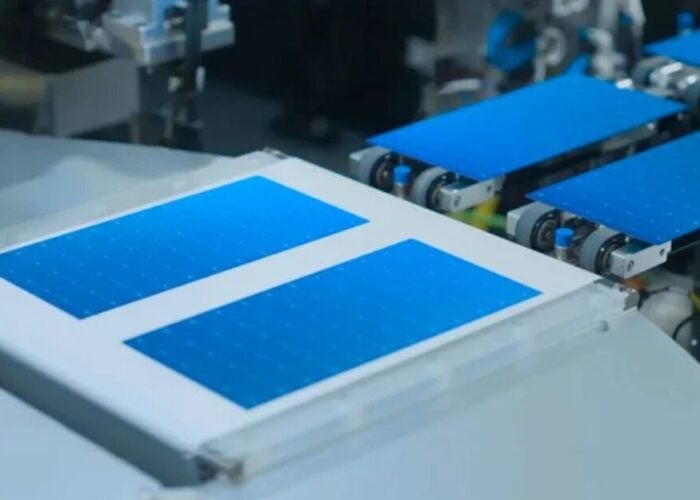

DuPont Microcircuit Materials has introduced its next-generation back side silver material for high-efficiency solar cells. DuPont Solamet’ PV51G photovoltaic metallization is claimed to decrease dependence on silver metals by reducing overall material consumption in solar cells up to 25%. Importantly, the material also provided improved adhesion and maintains desired efficiency performance of the cells.

Problem

Try Premium for just $1

- Full premium access for the first month at only $1

- Converts to an annual rate after 30 days unless cancelled

- Cancel anytime during the trial period

Premium Benefits

- Expert industry analysis and interviews

- Digital access to PV Tech Power journal

- Exclusive event discounts

Or get the full Premium subscription right away

Or continue reading this article for free

Reducing material costs to support aggressive reductions in overall PV module manufacturing costs continues to be a key importance as ASP declines continue. The high price of silver continues to be a key concern. Providing greater opportunities to reduce silver paste usage while helping higher conversion efficiencies is required.

Solution

Solamet PV51x series photovoltaic metallization paste products are tabbing conductors made with a breakthrough formulation that enables cell makers to use up to 25% less material and delivers comparable electrical performance versus the leading incumbent, according to the company. This helps reduce dependence on silver metals and offsets some of the impact that rising silver prices have on the cost of producing solar cells and modules. All the Solamet PV51x series products provide a wide printability window; ability to co-fire with current Solamet front side silver pastes as well as an improved adhesion window; reduced laydown, reduced tab footprint; and are made without lead or cadmium.

Applications

Back side silver metallization.

Platform

Solamet PV51G photovoltaic metallization back side paste is a highly conductive, solderable silver composition, developed to provide improved adhesion when used in conjunction with back side aluminum compositions. This paste may be co-fired with front side (n-type) silver conductors such as DuPont Solamet PV15x, PV16x, and PV17x and with back side (p-type) aluminum conductors such as DuPont Solamet PV3xx. Solamet PV51G is applied in a standard screen print process. The pastes are part of a broad portfolio of products represented by DuPont Photovoltaic Solutions (DPVS).

Availability

May 2012 onwards.