By Anne Jans Faber, Senior Scientist, CelSian Glass & Solar B.V.; Adriaan Lankhorst, R&D Manager, CelSian Glass & Solar B.V.; Bo Zhao, CTO, Jinggong Science & Technology Co., Ltd; Cheng Wang, R&D Manager, Jinggong Science & Technology Co., Ltd

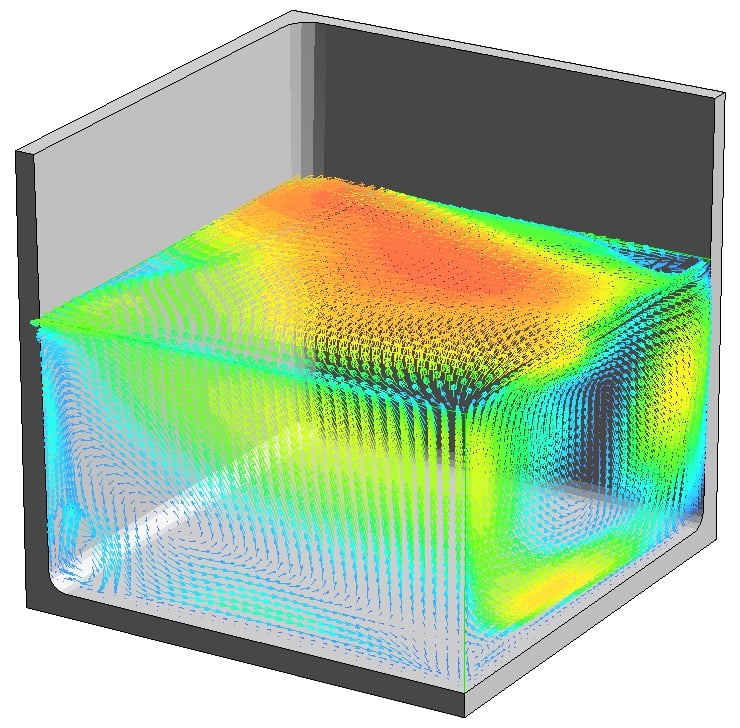

Unidirectional solidification of large Si ingots from the melt phase is currently one of the most important technologies for producing mc-Si for PV cells. Si ingot furnaces began from casting equipment, and have been improved by DSS (directional solidification system) or DSS-like methods. To improve PV cell efficiency and reduce costs, intensive development has focused on increasing a single ingot’s volume, reducing impurities and controlling the growth speed and temperature gradient. One of the latest developments of Si ingot furnaces is mono-like crystalline silicon growth using a seed preservation method and more accurate control. The Si ingot furnaces are optimized with precise control of temperature gradients and growth speed for the formation of a large unit of quasi-monocrystalline Si. This optimization can further improve a PV cell’s efficiency by at least 1%. In order to obtain fundamental knowledge about the key process steps that determine the growth and electrical quality of mc-Si via directional solidification in an ingot furnace, a combined modelling-measuring approach is essential. Moreover, a mathematical model of the Si ingot casting process can be used for model-based process control.