By Jian Chen, Jiangsu Sainty Machinery Import & Export Corp., Ltd.; JianGuo Chen, PV Engineer, Jiangsu Sainty Machinery Import & Export Corp., Ltd.; XiChen Wang, Jiangsu Sainty Machinery Import & Export Corp., Ltd.

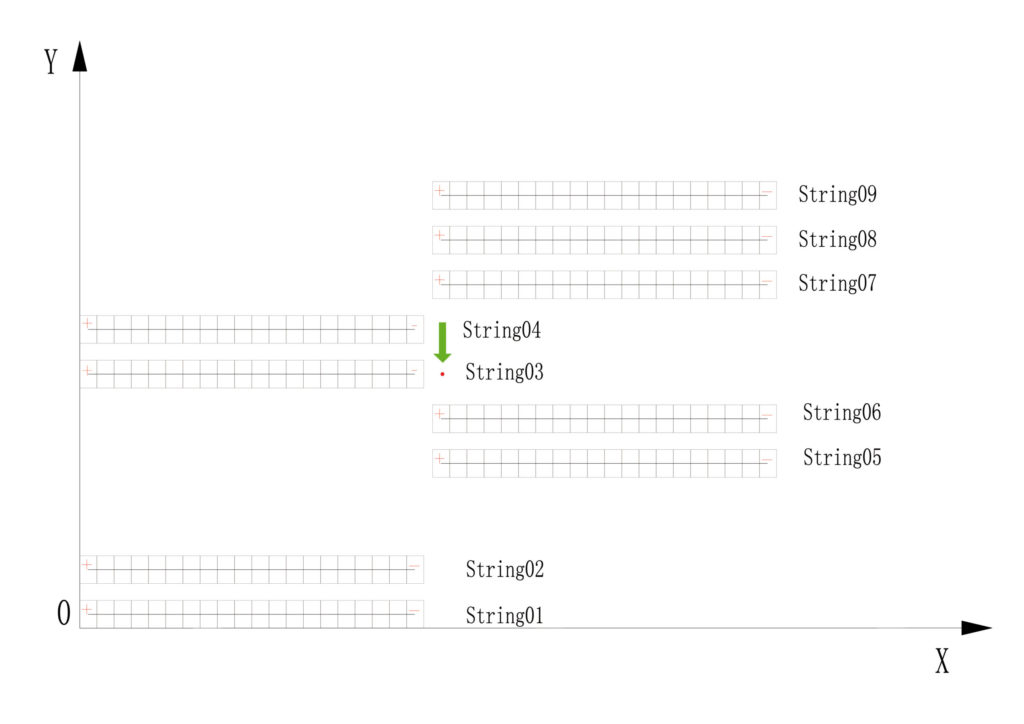

In PV power systems the choice of an appropriate location for the installation of the PV array box (or DC combiner box) is an important undertaking. It is essential that the box be placed so that the amount of DC cabling is minimized in order to not only save cable costs but also reduce voltage losses. This paper presents a fast solution to this problem, based on a mathematical model for the minisum location of the combiner according to the Manhattan metric between the PV array and the DC combiner box. The target function and its optimal solution (i.e. the most economical amount of cabling) for this particular model were obtained, and the optimality of the solution proved by contradiction. The application of this model is illustrated by means of two typical examples, involving an odd and an even number of strings in a PV array. The proposed model is efficient and easy to apply, and as such should be of interest to PV engineers and designers.