By Nils-Peter Harder, Head of the High-efficiency Silicon Solar Cells Group, Institute for Solar Energy Research Hamelin (ISFH); Agnes Merkle, Institute for Solar Energy Research Hamelin (ISFH); Till Brendemühl, Engineer, Developing Laser Processes, Institute for Solar Energy Research Hamelin (ISFH); Fabian Kiefer, Institute for Solar Energy Research Hamelin (ISFH); Ralf Gogolin, Institute for Solar Energy Research Hamelin (ISFH); Martin Lehr, Institute for Solar Energy Research Hamelin (ISFH); Frank Heinemeyer, Project Leader in the Process Technology Group, Institute for Solar Energy Research Hamelin (ISFH); Henning Schulte-Huxel, Institute for Solar Energy Research Hamelin (ISFH); Bianca Lim, Institute for Solar Energy Research Hamelin (ISFH); Verena Jung, Institute for Solar Energy Research Hamelin (ISFH); Sarah Kajari-Schröder, Institute for Solar Energy Research Hamelin (ISFH); Marc Köntges, Institute for Solar Energy Research Hamelin (ISFH); Rolf Brendel, Institute for Solar Energy Research Hamelin (ISFH)

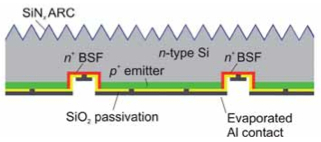

This paper presents ISFH’s recent developments and advances in the field of back-contacted silicon solar cells. The efficiency potential of back-contacted solar cells is very high; nevertheless, in industrial production, back-contacted solar cells are decidedly the minority. In the field of back-contacted solar cells, ISFH has developed several cell concepts and new processing techniques, such as laser ablation for silicon structuring, contact opening through passivation layers, and hole drilling for emitter-wrap-through (EWT) solar cells. The latest results are presented regarding ISFH’s work on back-junction back-contacted solar cells and EWT solar cells, as well as on back-contacted solar cells employing an amorphous/crystalline silicon heterojunction. Also discussed are the advances in high-throughput evaporation of aluminium as a low-cost option for the metallization of back-contacted solar cells. Finally, a novel, silver-free cell interconnection technique is presented, which is based on the direct laser welding of a highly conductive, low-cost Al foil, as a cell interconnect, onto the rear side of back-contacted solar cells.