By Angela De Rose; Torsten Geipel; Denis Erath; Achim Kraft; Ulrich Eitner, Fraunhofer Institute for Solar Energy Systems ISE, Freiburg, Germany

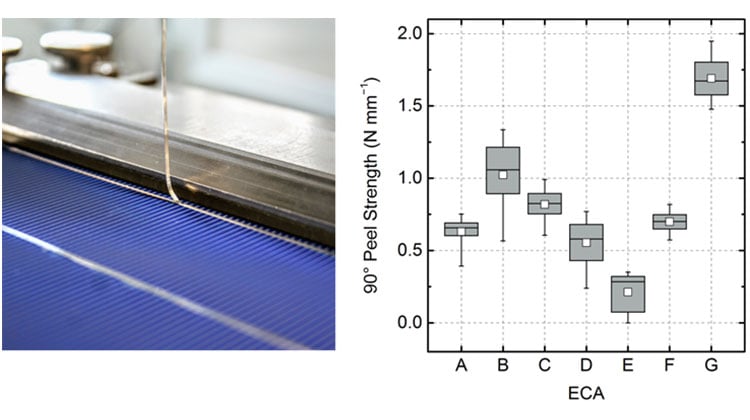

Crystalline silicon heterojunction (HJT) solar cells and modules based on amorphous silicon on monocrystalline wafers offer advantages over established wafer-based technologies in terms of efficiency potential, complexity of the manufacturing process, and energy yield of the modules. The temperature sensitivity of these solar cells, however, poses considerable challenges for their integration in modules. Currently, there exist three approaches for the interconnection of HJT solar cells, each with its own strengths and weaknesses: 1) ribbon soldering with low-meltingpoint alloys; 2) gluing of ribbons by using electrically conductive adhesives (ECAs); 3) SmartWire Connection Technology (SWCT).