By Eckard Wefringhaus, Director of the Quality Management Department, ISC Konstanz; Florian Buchholz, Quality Management Department, ISC Konstanz

This paper discusses the role of wafer cleaning in solar cell processing, and addresses its increasing importance with the introduction of new process steps for manufacturing high-efficiency solar cells. The requirements for

cleaning before several process steps, in relationship to the solar cell production sequence, are discussed: frontend- of-the-line (FEOL) cleaning needs to reduce metal surface concentrations by several orders of magnitude (residues from wafer sawing), while back-end-of-the-line (BEOL) cleaning needs to reduce mostly process induced contamination, which tends to be much lower. A ten-step roadmap for process integration and

optimization of new cleaning processes from lab to fab is suggested, which is based on process analytics and simple bath-lifetime simulations. A number of advanced cleaning steps are identified and their suitability for

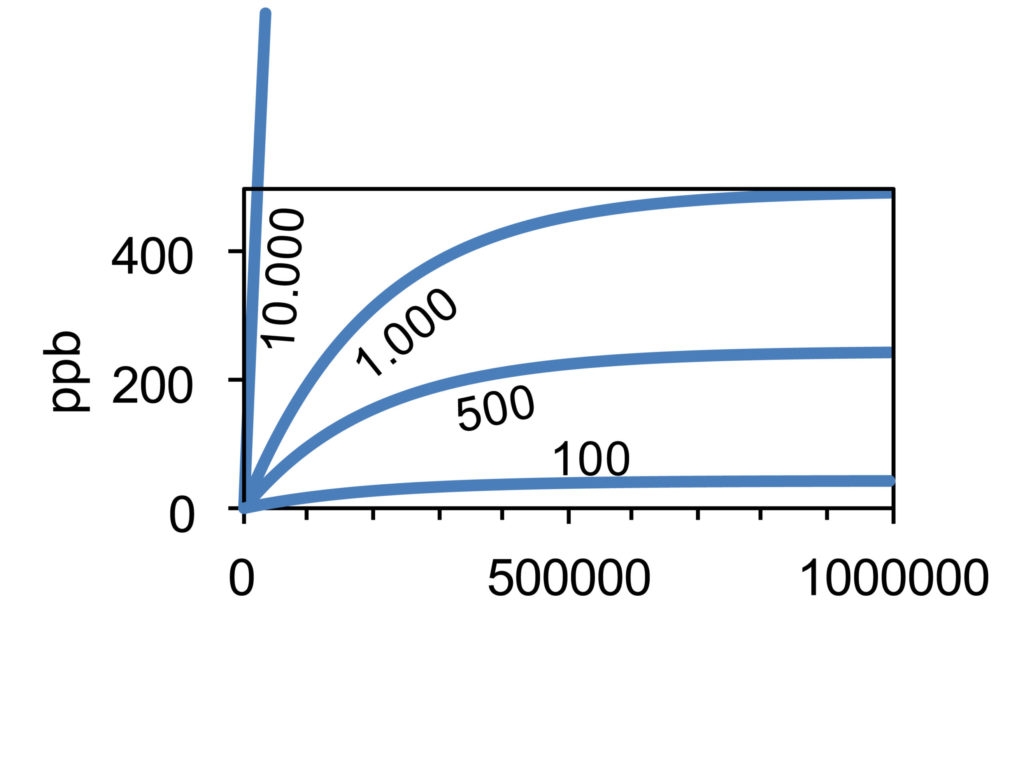

solar cell mass production is examined. The influence of the different input variables is demonstrated, with a focus on feed and bleed settings. Finally, the need for constant monitoring of cleaning baths is highlighted, and

a device developed by Metrohm for cost-effective on-site monitoring of metallic contamination is discussed.