By Volker Sittinger, Senior Scientis, Large Area Coating Department, Fraunhofer IST; Wilma Dewald, Junior Scientist, Magnetron Sputtering Group, Fraunhofer IST; Wolfgang Werner, Fraunhofer IST; Bernd Szyszka, Head of the Department of Large Area Coatings, Fraunhofer IST; Florian Ruske, Scientist, Helmholtz-Zentrum Berlin für Materialien und Energie GmbH

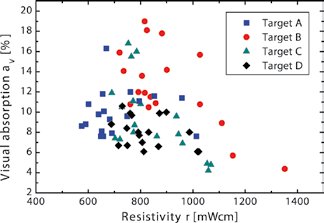

Highly conductive transparent films are of significant interest in the field of thin-film photovoltaics. ZnO-based films in particular have attracted much interest due to the low cost of materials with good film properties for CIGS and a-Si/µc-Si solar modules. Investigations have been ongoing at Fraunhofer IST into ceramic ZnO:Al2O3 targets from different manufacturers. This paper presents a comparison of target material, sputter characteristics and film properties of ZnO:Al. Sputter characteristics are in this case determined by voltage and current data showing arcing rates at different power loads and process pressures. ZnO:Al films are deposited by DC magnetron sputtering with various deposition parameters (e.g oxygen flow, total pressure, sputtering power and substrate temperature) and investigated with respect to optical and electrical properties. A correlation between film properties, sputter characteristics and target material can therefore be determined. As it appears that arcing has the biggest influence on film properties, the ceramic target material can be optimized for minimal arcing.