By Ian Bennett, Energy Research Centre of the Netherlands (ECN); Bart Geerligs, Researcher, Energy Research Centre of the Netherlands (ECN); Carol Olson, Project Manager, Energy Research Centre of the Netherlands (ECN); Maurice Goris, Chemical Engineer, Energy Research Centre of the Netherlands (ECN)

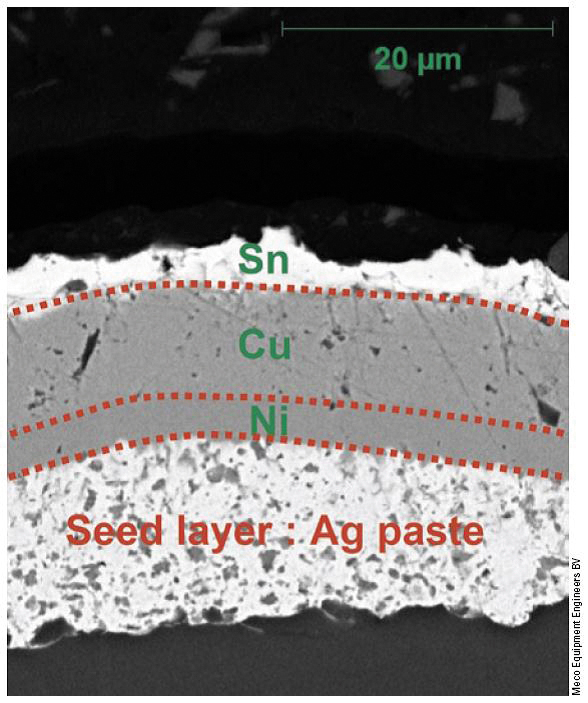

As part of the European FP7 R&D project ‘Cu-PV’, the compatibility of copper-electroplated metal wrapthrough (MWT) cells with conductive adhesives has been investigated. The objectives of this project include to reduce, by the use of copper plating, the amount of silver utilized in cell manufacturing, and to demonstrate the compatibility of high-power n-type back-contact module technology with copper-plated cells. The overall goal is to reduce the impact on the environment of cell and module manufacture. MWT module technology as developed by ECN uses conductive adhesive to make the interconnection between cells and a conductive backsheet foil. These adhesives have been proved to result in very reliable modules in the case of cells with fired silver metallization. To determine the compatibility of conductive adhesive with copper-plated cells, component tests were performed, followed by the manufacture of modules with copperplated cells and conductive adhesive interconnections. Climate chamber testing of these modules showed that the adhesive is compatible with the copper-plated cells. The next steps include further optimization of the plating process and additional testing at the module level.