By Jonas Haunschild, luminescence Imaging Team Leader, Fraunhofer ISE; Juliane Broisch, In-line Measurement Techniques and Quality Assurance Group, Fraunhofer ISE; Isolde Reis, Member of the luminescence Imaging Team, Fraunhofer ISE; Stefan Rein, Head of the In-line Measurement Techniques and Quality Assurance Group, Fraunhofer ISE

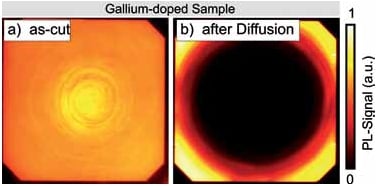

Most high-efficiency solar cells are fabricated from monocrystalline Czochralski silicon (Cz-Si) wafers because the material quality is higher than multicrystalline silicon (mc-Si) wafers. However, the material study presented in this paper reveals strong variations in the material quality of commercially available Cz-Si wafers, leading to a loss in solar cell efficiency of 4% absolute. The reason for this is the presence of defects, which appear as dark rings in photoluminescence (PL) images of the finished solar cells. It is shown that these efficiency-limiting defects originate from oxygen precipitation during emitter diffusion. It is demonstrated that an incoming inspection in the as-cut state is difficult, as strong ring structures in as-cut wafers turn out to originate most often from thermal donors. These are dissolved during high-temperature treatments and are therefore harmless, whereas moderate ring structures in the as-cut state may become severe. That is why critical wafers can be identified and sorted out reliably only after emitter diffusion, by using QSSPC-based lifetime measurements or PL imaging. The two-year statistics gathered from the research line at Fraunhofer ISE on the occurrence of ring defects in Cz-Si wafers indicate that ring defects are highly relevant in terms of material yield.